Rundstange Gezogen

Rundrohre Gezogen

5052

Cold Drawn/Finished (CF) / AlMg2.5 (Soğuk Çekim) / 5052 / H14

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,25 |

| Chromium (Cr) | 0,15 - 0,35 |

| Manganese (Mn) | 0,00 - 0,10 |

| Magnesium (Mg) | 2,20 - 2,80 |

| Copper (Cu) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,40 |

| Zinc (Zn) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.68 g/cm³ |

| Melting Point | 607 °C |

| Thermal Expansion | 23.8 µm/m.°C |

| Modulus of Elasticity | 68 GPa |

| Thermal Conductivity | 140 W/m.K |

| Electrical Resistivity | %35 IACS |

| Mechanical Properties | Value |

| Proof Strength | 200 MPa |

| Yield Strength | 250 MPa |

| Shear Strength | 145 MPa |

| Elongation A50 mm | 11% |

| Hardness | 69 HB |

ALLOY DESIGNATIONS

5052 H14 has the following standard designations and specifications.

Sheets per; 5052 H14, AMS QQ-A-250/8, ISO AlMg2.5, WNR 3.3523, UNS A95052, ASTM B209

Cold Drawn Round/Flat Bar and Wires per; 5052 H14, ASTM B211, ISO AlMg2.5, WNR 3.3523, WW-T-700/4, AMS QQ-A-225/7

Cold Drawn Tubes per; 5052 H14, ASTM B210, ISO AlMg2.5, WNR 3.3523

Choosing Factors for 5052 H14

- Strength: Mediocre

- Machining: Good

- Weldability: High

- Formability: Decent

- Corrosion Resistance: Perfect

- Heat Treating: None

Some Well-Known Applications for 5052 H14

In packaging materials and pallets,

In electronic circuits,

Also used in the aviation sector in fuel manufacturing pipes of aircraft.

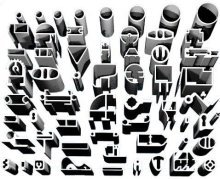

SUPPLIED FORMS

5052 H14 is produced/supplied in sheet round/flat bar and tube/profile forms.

- Tube/Profile

- Sheet

- Round/Flat Bar

DELIVERY:

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 0.2 up to & incl. 0.5 | 234 | 283 | %3 |

| Over 0.5 up to & incl. 1.2 | 234 | 283 | %4 |

| Over 1.2 up to & incl. 2.9 | 234 | 283 | %6 |

Gewichts-Kalkulator

Gewichts-Kalkulator