5086

UNS A95086 / AlMg4 / 5086 / H22

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,05 - 0,25 |

| Magnesium (Mg) | 3,50 - 4,50 |

| Manganese (Mn) | 0,20 - 0,70 |

| Titanium (Ti) | 0,00 - 0,15 / - |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,66 g/cm³ |

| Melting Point | 585 °C |

| Thermal Expansion | 23.8 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | 31% IACS |

| Mechanical Properties | Value |

| Proof Strength | 220 MPa |

| Yield Strength | 300 MPa |

| Shear Strength | 180 MPa |

| Elongation A50 mm | 20% |

| Hardness | 78 HB |

5086 aluminum exhibits higher strength than 5052 and has excellent corrosion resistance in marine and salt water environments. It is easy to form, stamp and weld.

ALLOY DESIGNATIONS

5086 H22 has the following standard designations and specifications.

As Plate/Sheet; 5086 H22, AMS QQ-A-250/7, ASTM B209, ISO AlMg4, DIN AlMg4Mn UNS A95086, ASTM B632, ASTM B928, AMS QQ-A-250/19, WNR 3.3545

As Cold Drawn 5086 H22, ASTM B211, UNS A95086, ASTM B928, ASTM B210, WNR 3.3545, DIN AlMg4Mn

Choosing Factors for 5086 H22

- Strength: Very good

- Machining: Good

- Weldability: Fairly good

- Formability: Good

- Corrosion Resistance: Great

- Heat Treating: Yes

Some Well-Known Applications for 5086 H22

On yacht, ship and boat bridges and hulls,

In drilling and oil rigs and refineries,

In addition to cariogenic applications, it is used in armored military personnel carriers and as a tank component.

SUPPLIED FORMS

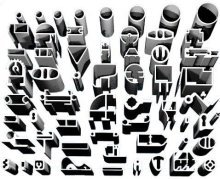

5086 H22 is produced/supplied in plate/sheet, round/flat bar and tube/profile forms.

- Plate

- Sheet

- Rod / Round Bar / Flat Bar

- Tube/Profile

DELIVERY:

Gewichts-Kalkulator

Gewichts-Kalkulator