قضبان مستديرة مرسومة على البارد

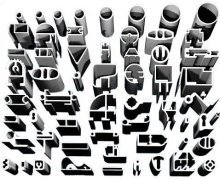

أنابيب الألمنيوم المسحوبة على البارد

2007

Cold Drawn/Finished (CF) / AlCu4PbMgMn (Soğuk Çekim) / 2007 / T3511

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,80 |

| Copper (Cu) | 3,30 - 4,60 |

| Lead (Pb) | 0,80 - 1,50 |

| Iron (Fe) | 0,00 - 0,80 |

| Zinc (Zn) | 0,00 - 0,80 |

| Nickel (Ni) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| Magnesium (Mg) | 0,40 - 1,80 |

| Manganese (Mn) | 0,50 - 1,00 |

| Physical Properties | Value |

| Density | 2.82 g/cm³ |

| Melting Point | 510 °C |

| Thermal Expansion | 23.0 µm/m.°C |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | %47 IACS |

| Mechanical Properties | Value |

| Proof Strength | 270 MPa |

| Yield Strength | 410 MPa |

| Shear Strength | 240 MPa |

| Elongation A50 mm | 5.6% |

| Hardness | 72 HB |

The cold-drawn 2007 T3511 aluminum alloy stands out for its high strength, light weight, and excellent machinability. This alloy is commonly used in automotive, aerospace, marine, and other industrial applications. As part of the aluminum-copper alloy class, the 2007 T3511 is particularly favored for structural components that require high strength.

The alloy is suitable for anodizing, which creates a protective oxide layer on the surface, providing enhanced corrosion resistance and an aesthetically pleasing finish. Its weldability is moderate and requires the use of proper techniques to ensure durable welds. When applied correctly, welded joints can achieve high strength.

The 2007 T3511 aluminum alloy is highly suitable for bending and shaping, offering great flexibility for producing complex geometries. Additionally, it can be used in high-vibration environments, as its robust structure resists vibrations and performs reliably under challenging conditions.

With its high corrosion resistance, the 2007 T3511 is ideal for marine and other humid environments. Moreover, its light weight improves portability, making it a popular choice in industries like automotive and aerospace.

The alloy’s advantages include high strength, good machinability, corrosion resistance, and anodizing compatibility. However, it has some drawbacks, such as challenges in welding and limited resistance to high temperatures. Overall, the 2007 T3511 aluminum alloy is an excellent choice for industrial applications, though attention should be given to welding processes and temperature resistance.

Cold Drawn Tubes per; 2007 T351, WNR 3.1645, DIN AlCuMgPb, AFNOR A-U4Pb, UNI 9002/8, UNE L-3121, UNS A92007, ISO AlCu4PbMgMn, ASTM B210

Choosing Factors for 2007 T3511

- Strength: High

- Machining: Good

- Weldability: Weak

- Formability: Poor

- Corrosion Resistance: Poor

- Heat Treating: Yes

Some Well-Known Applications for 2007 T3511

In the automotive industry,

As components of ammunition in the defense industry,

It is also used in electric fans.

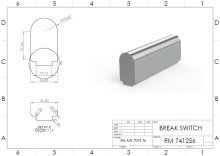

- Tube

حساب الوزن

حساب الوزن