5005

ASTM B209 / AlMg1 / 5005 / H34

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,30 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,20 - 0,40 |

| Magnesium (Mg) | 0,50 - 1,10 |

| Copper (Cu) | 5,80 - 6,80 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 632 °C |

| Thermal Expansion | 23.8 µm/m.°C |

| Modulus of Elasticity | 68 GPa |

| Thermal Conductivity | 200 W/m.K |

| Electrical Resistivity | 52% IACS |

| Mechanical Properties | Value |

| Proof Strength | 138 MPa |

| Yield Strength | 160 MPa |

| Shear Strength | 96 MPa |

| Elongation A50 mm | 7% |

| Hardness | 41 HB |

5005 H34 has excellent finishing qualities and anodized coatings. Weldability is very good and 5005 H34 has good resistance to corrosion, especially in anodised. Alloy 5005 H34 sheet is typically used in interior & exterior architecture and design.

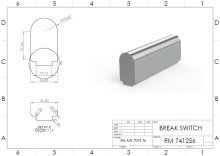

ALLOY DESIGNATIONS

5005 H34 has the following standard designations and specifications.

Sheets per; 5005 H34, ISO AlMg1, DIN AlMg1, WNR 3.3315, UNS A95005, ASTM B209, BS N41

Cold Drawn Round/Flat Bar per; 5005 H34, ISO AlMg1, DIN AlMg1, WNR 3.3315, UNS A95005, ASTM B211

Cold Drawn Tubes per; 5005 H34, ISO AlMg1, DIN AlMg1, WNR 3.3315, UNS A95005, ASTM B210

Choosing Factors for 5005 H18

- Strength: Medium

- Machining: Fair

- Weldability: Very good

- Formability: Good

- Corrosion Resistance: Perfect

- Heat Treating: None

Some Well-Known Applications for 5005 H18

In anodized parts,

Traffic and road signs and signage in general,

Also used in architectural applications.

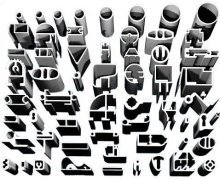

SUPPLIED FORMS

5005 H18 is produced/supplied in the sheet, tube/profile, round/flat bar forms.

- Sheet

- Round/Flat Bar

- Tube/Profile

DELIVERY:

حساب الوزن

حساب الوزن