Platten

Blech

Rundstangen

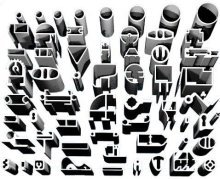

Rohre/ Extrusion/ Profil

7075

QQ-A-250/12 / AlZn5.5MgCu / 7075 / F

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,10 - 2,90 |

| Copper (Cu) | 1,20 - 2,00 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 5,10 - 6,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.81 g/cm³ |

| Melting Point | 466°C |

| Thermal Expansion | 23 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 173 W/m.K |

| Electrical Resistivity | 33 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 125 MPa |

| Yield Strength | 245 MPa |

| Shear Strength | 153 MPa |

| Elongation A50 mm | 12% |

| Hardness | 59 HB |

7075 F Sheet is a factory-production output aluminum alloy which is mostly produced by aiming the project values in where it will be used.

ALLOY DESIGNATIONS

7075 F has the following standard designations and specifications.

Sheet and Plate / Plate as; 7075 F, AMS QQ-A-250/12, ASTM B209

Choosing Factors for 7075 F:

- Strength: Normal

- Machining: Fair

- Weldability: Week

- Formability: Low

- Corrosion Resistance: Average

- Heat Treating:Yes

TEMPER TYPES

AMS QQ-A-250/12 7075 is supplied in the following heat treatment types:

- O

- F

- T651

- T73

- T7351

Some Well-Known Applications for 7075 F:

Automotive industry.

It is used in the production of spare parts produced by hot and cold forming.

Machine equipment and equipment production, forging and press operations.

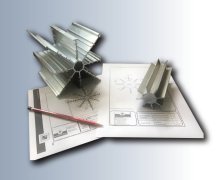

SUPPLIED FORMS

7075 F is supplied in plate, sheet, and bar / round bar / flat bar form.

- Plate

- Sheet

- Rod / Round Bar / Flat Bar

DELIVERY:

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 0.4 up to & incl. 12.5 | 145 MPa | 275 MPa | %10 |

Gewichts-Kalkulator

Gewichts-Kalkulator