2017

UNS A92017 / AlCu4MgSi / 2017 / O

| Chemical Properties | % Value |

| Silicon (Si) | 0,20 - 0,80 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,40 - 1,0 |

| Magnesium (Mg) | 0,40 - 1,00 |

| Copper (Cu) | 3,50 - 4,50 |

| Titanium (Ti) | 0,00 - 0,25 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.79 g/cm³ |

| Melting Point | 510 °C |

| Thermal Expansion | 22.9 µm/m.°C |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 140 W/m.K |

| Electrical Resistivity | 38 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 76 MPa |

| Yield Strength | 190 MPa |

| Shear Strength | 130 MPa |

| Elongation A50 mm | %15 |

| Hardness | 45 HB |

2017 O aluminum exhibits mid strength and is used in high strength structural components for aircraft , military vehicles and bridges, weapons manufacture, structural applications etc.

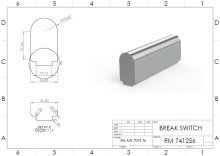

ALLOY DESIGNATIONS

2017 O has the following standard designations and specifications.

As Sheet/Plate; 2017 O, ASTM B209, ISO AlCu4MgSi, UNS A92017, WNR 3.1325, DIN AlCuMg1

As Extruded Round/Flat Bar; 2017 O, AMS QQ-A-200/2, ASTM B221, UNS A92017, WNR 3.1325, DIN AlCuMg1

As Cold Drawn Round/Flat Bar: 2017 O, AMS QQ-A-225/5, ASTM B211, UNS A92017, WNR 3.1325, DIN AlCuMg1, ASTM B565, ASTM B316,

Choosing Factors for 2017 O

- Strength: Moderate

- Machining: Excellent

- Weldability: Average

- Formability: Good

- Corrosion Resistance: Fair

- Heat Treating: Yes

Some Well-Known Applications for 2017 O

It is used in hydraulic applications, rivets,

In military vehicles and materials,

It is also used in automatic screwing machines.

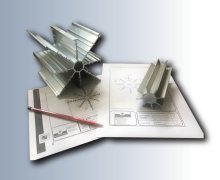

SUPPLIED FORMS

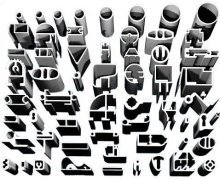

2017 O is produced/supplied in plate/sheet, round/flat bar and tube/profile forms.

- Plate/Sheet

- Rod / Round Bar / Flat Bar

- Tube/Profile

DELIVERY:

حساب الوزن

حساب الوزن