1200

BS 3L54 / Al99 / 1200 / F

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 1,00 |

| Manganese (Mn) | 0,00 - 0,05 |

| Copper (Cu) | 0,00 - 0,05 |

| Lead (Pb) | 0,00 - 0,05 |

| Titanium (Ti) | 0,00 - 0,05 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 657 °C |

| Thermal Expansion | 23.4 µm/m.°C |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 225 W/m.K |

| Electrical Resistivity | %58.5 IACS |

| Mechanical Properties | Value |

| Proof Strength | 28 MPa |

| Yield Strength | 85 MPa |

| Shear Strength | 54 MPa |

| Elongation A50 mm | 23% |

| Hardness | 27 HB |

1200 F is an aluminum that may be clad with other 7000 series alloys for better resistance against stress corrosion cracking. It exhibits low strength and is widely used in aerospace and general industry applications..

ALLOY DESIGNATIONS

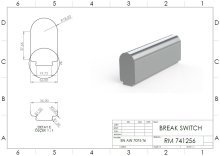

Sheets per; 1200 F, ASTM B209, BS 6 L16, UNS A91200, BS 1C, ISO Al99.0, DIN Al99, WNR 3.0205

Extruded Tubes and Profiles per; 1200 F, ASTM B221, UNS A91200, BS 1C, ISO Al99.0, DIN Al99, WNR 3.0205, BS 3L 54

Choosing Factors For 1200 F

- Strength: Low

- Machining: Poor

- Weldability: Perfect

- Formability: Exquisite

- Corrosion Resistance: Very good

- Heat Treating: None

Some Well-Known Applications for 1200 F

On railway vagons,

In the mechanical-chemical industry,

It is also used in shipbuilding and as a component of holloware.

SUPPLIED FORMS

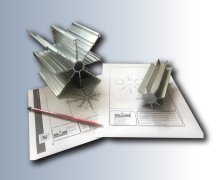

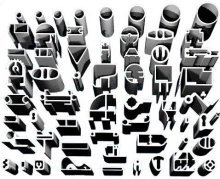

1200 F is produced/supplied in the sheet, round/flat bar and tube/profile form.

- Sheets

- Tube/Profile

DELIVERY:

Calculateur de Poids

Calculateur de Poids