Калиброванные прутки

Трубы волоченые

2033

Cold Drawn/Finished (CF) / AW-2033 (Soğuk Çekim) / 2033 / T351

| Chemical Properties | % Value |

| Silicon (Si) | 0,10 - 1,20 |

| Chromium (Cr) | 0,00 - 0,15 |

| Manganese (Mn) | 0,40 - 1,00 |

| Magnesium (Mg) | 0,20 - 0,60 |

| Copper (Cu) | 2,20 - 2,70 |

| Titanium (Ti) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,50 |

| Aluminium (Al) | Balance |

| Nickel (Ni) | 0,00 - 0,15 |

| Physical Properties | Value |

| Density | 2.78 g/cm³ |

| Melting Point | 502 °C |

| Thermal Expansion | 22,9 µm/m.°C |

| Modulus of Elasticity | 73.1 GPa |

| Thermal Conductivity | 151 W/m.K |

| Electrical Resistivity | 0,046 Ωmm² /m |

| Mechanical Properties | Value |

| Proof Strength | 220 MPa |

| Yield Strength | 370 MPa |

| Shear Strength | 283 MPa |

| Elongation A50 mm | 8% |

| Hardness | 95 HB |

The cold-drawn 2033 T351 aluminum alloy is known for its high strength, excellent machinability, and fatigue resistance. It is widely used in aerospace, automotive, and heavy industrial sectors, particularly for load-bearing parts subject to impacts. While its copper content enhances durability, it naturally has limited corrosion resistance, so anodizing or additional protective coatings are recommended for harsh environments. Its suitability for anodizing enhances surface hardness, extends durability, and provides an improved aesthetic appearance.

Due to its limited weldability, 2033 T351 is typically assembled using mechanical fastening methods like bolting or riveting. The cold-drawing process improves its formability and bendability, making it adaptable to complex shapes. Additionally, it performs reliably in high-vibration environments, which makes it ideal for moving parts and applications where fatigue resistance is critical. Key advantages include high strength, bendability, machinability, and anodizing compatibility, while drawbacks include limited corrosion resistance and challenging weldability. These properties make 2033 T351 aluminum alloy an excellent choice for projects demanding durability, strength, and vibration resistance.

ALLOY DESIGNATIONS

Aluminium alloy 2033 T351 has similarities to the following standard designations and specifications:

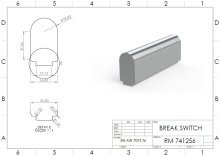

Cold Drawn Round/Flat Bars per; 2033 T351, 2000/53/EU (ELV) - 2018/740/EU (RoHS II), UNS A92033, ASTM B211

Cold Drawn Tubes per; 2033 T351, 2000/53/EU (ELV) - 2018/740/EU (RoHS II), UNS A92033, ASTM B210

Choosing Factors for 2033 T351

- Strength: Very good

- Machining: Excellent

- Weldability: Mediocre

- Formability: Acceptable

- Corrosion Resistance: Low

- Heat Treating: Yes

Some Well-Known Applications for 2033 T351

In threaded parts,

In the defense industry,

It is also used in pressure stamping machines.

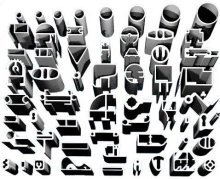

SUPPLIED FORMS

2033 T351 is supplied in round/flat bar and tube/ profile forms.

- Flat/round bar

- Tube/profile

Калькулятор Веса

Калькулятор Веса