2030

EN AW / AlCu4PbMg / 2030 / T4511

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,80 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,20 - 1,00 |

| Magnesium (Mg) | 0,50 - 1,30 |

| Copper (Cu) | 3,30 - 4,50 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,50 |

| Lead (Pb) | 0,80 - 1,50 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.82 g/cm³ |

| Melting Point | 520 °C |

| Thermal Expansion | 23 µm/m.°C |

| Modulus of Elasticity | 73,6 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | 34 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 240 MPa |

| Yield Strength | 370 MPa |

| Shear Strength | 220 MPa |

| Elongation A50 mm | 7% |

| Hardness | 85 HB |

A medium to high strength alloy with, dependent upon temper, minimum Proof Stress up to 57 ksi / 390 Mpa and minimum Tensile Strength up to 66 ksi / 455 MPa

ALLOY DESIGNATIONS

Aluminium alloy 2030 T4511 has similarities to the following standard designations and specifications:

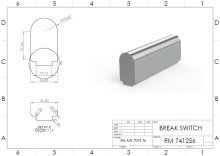

Extruded Round/Flat Bar and Tubes per; 2030 T4511, ISO AlCu4PbMg, DIN AlCuMgPb , UNS A92030, ASTM B221, AFNOR AU4Pb

Choosing Factors for 2030 T4511

- Strength: Very good

- Machining: Excellent

- Weldability: Satisfactory

- Formability: Moderate

- Corrosion Resistance: Low

- Heat Treating: Yes

Some Well-Known Applications for 2030 T4511

In bolt and screw manufacturing,

In high speed turning lathes,

It is also used as components of sports equipments.

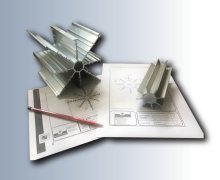

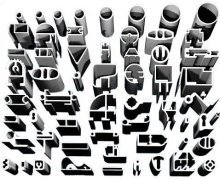

SUPPLIED FORMS

2030 T4511 is supplied in round/flat bar and tube/ profile forms.

- Flat/round bar

- Tube/profile

حساب الوزن

حساب الوزن