2030

AU4Pb / AlCu4PbMg / 2030 / T351

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,80 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,20 - 1,00 |

| Magnesium (Mg) | 0,50 - 1,00 |

| Copper (Cu) | 3,50 - 4,50 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,50 |

| Lead (Pb) | 0,80 - 1,00 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.82 g/cm³ |

| Melting Point | 520 °C |

| Thermal Expansion | 23 µm/m°C |

| Modulus of Elasticity | 73.6 GPa |

| Thermal Conductivity | 120 W/m.K |

| Electrical Resistivity | %40 IACS |

| Mechanical Properties | Value |

| Proof Strength | 270 MPa |

| Yield Strength | 410 MPa |

| Shear Strength | 240 MPa |

| Elongation A50 mm | 7% |

| Hardness | 95 HB |

2030 aluminum alloy is an alloy heavily used in the machine-mold industry. Being suitable for precise machined parts and its well formability makes it an ideal option for the automotive industry as well.

ALLOY DESIGNATIONS

Aluminium alloy 2030 T351 has similarities to the following standard designations and specifications:

Cold Drawn Round/Flat Bars per; 2030 T351, ISO AlCu4PbMg, DIN AlCuMgPb , UNS A92030, ASTM B211, AFNOR AU4Pb

Cold Drawn Tubes per; 2030 T351, ISO AlCu4PbMg, DIN AlCuMgPb , UNS A92030, ASTM B210, AFNOR AU4Pb

Choosing Factors for 2030 T351

- Strength: Perfect

- Machining: Excellent

- Weldability: Satisfactory

- Formability: Moderate

- Corrosion Resistance: Weak

- Heat Treating: Yes

Some Well-Known Applications for 2030 T351

Nuts and thredad bars,

In hydraulic cylinders,

It is dominantly used in the automotive industry.

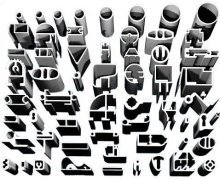

SUPPLIED FORMS

2030 T351 is supplied in round/flat bar and tube/ profile forms.

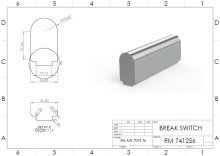

- Flat/round bar

- Tube/profile

حساب الوزن

حساب الوزن