Platos

Hojas

Barras Circulares

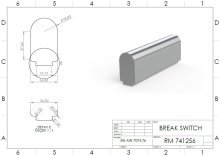

Tubos / Extrusion / Perfil

6026

ASTM B241 / AlMg2.5SiMnCu / 6026 / T6

| Chemical Properties | % Value |

| Silicon (Si) | 0,40 - 0,80 |

| Chromium (Cr) | 0,04 - 0,35 |

| Manganese (Mn) | 0,00 - 0,15 |

| Magnesium (Mg) | 0,80 - 1,20 |

| Copper (Cu) | 0,15 - 0,40 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.72 g/cm³ |

| Melting Point | 582 °C |

| Thermal Expansion | 23.4 x 10^-6 /K |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 172 W/m.k |

| Electrical Resistivity | 0,039 Ωmm² /m |

| Mechanical Properties | Value |

| Proof Strength | 300 MPa |

| Yield Strength | 370 MPa |

| Shear Strength | 257 MPa |

| Elongation A50 mm | 8% |

| Hardness | 95 HB |

6026 aluminum alloy, which has excellent corrosion resistance and is suitable for anodizing, does not contain tin (Sn) element, as it is known for causing cracking in processed parts at high pressure and temperature. Developed meeting the following norms and directives of the European Union as an alternative alloy to 6061 and 6082, the extrusion bars of 6026 alloy also have the same minimum tensile strength value as 2011 and 2030 alloys.

ALLOY DESIGNATIONS

6026 T6 has the following standard designations and specifications.

Extruded Round/Flat Bars per; 6026 T6, 2000/53/CE-ELV (Otomotiv için), 2002/95/CE-RoHS, ASTM B221, UNS A96026

Extruded Seamless Tubes per; 6026 T6, 2000/53/CE-ELV (Otomotiv için), 2002/95/CE-RoHS, ASTM B241, UNS

Cold Drawn Round/Flat Bars per; 6026 T6, 2000/53/CE-ELV (Otomotiv için), 2002/95/CE-RoHS, ASTM B211, UNS A96026

Cold Drawn Tubes per; 6026 T6, 2000/53/CE-ELV (Otomotiv için), 2002/95/CE-RoHS, ASTM B210, UNS A96026

Choosing Factors for 6026 T6

- Strength: Moderate

- Machining: Excellent

- Weldability: Good

- Formability: Fair

- Corrosion Resistance: Great

- Heat Treating: Yes

Some Well-Known Applications for 6026 T6

In electrics and electronic parts,

In the automotive industry,

It is also used in high-speed automotic lathes for extensive machining.

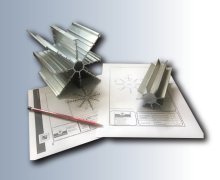

SUPPLIED FORMS

6061 T6 is produced/supplied in plate/sheet round/flat bar and tube/profile forms.

- Rod / Round Bar / Flat Bar

- Plate

- Sheet

- Tube/Profile

DELIVERY:

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 2.5 up to & incl. 140 mm | 300 MPa | 370 MPa | 8% |

| Over 140 up to & incl. 200 mm | 250 MPa | 340 MPa | 8% |

| Over 200 up to & incl. 250 mm | 200 MPa | 300 MPa | 8% |

Calculador de Peso

Calculador de Peso