Dalle

Tôle

Barre ronde

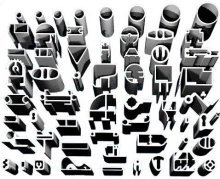

Tube/ Extrusion/ Profil

6005A

ASTM B211 / AlSiMg(A) / 6005A / T4

| Chemical Properties | % Value |

| Silicon (Si) | 0,50 - 0,90 |

| Chromium (Cr) | 0,00 - 0,30 |

| Manganese (Mn) | 0,00 - 0,50 |

| Magnesium (Mg) | 0,40 - 0,70 |

| Copper (Cu) | 0,00 - 0,30 |

| Titanium (Ti) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,35 |

| Zinc (Zn) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.63 g/cm³ |

| Melting Point | 582 °C |

| Thermal Expansion | 23.4 µm/m°C |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 190 W/m.K |

| Electrical Resistivity | 49% IACS |

| Mechanical Properties | Value |

| Proof Strength | 100 MPa |

| Yield Strength | 200 MPa |

| Shear Strength | 120 MPa |

| Elongation A50 mm | %15 |

| Hardness | 69 GPa |

6005A alloy, which exhibits mechanical values in between that of 6061 and 6082 is welded best using arc welding and has superior corrosion resistance and good anodizing.

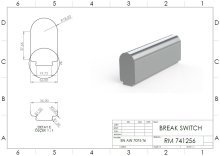

ALLOY DESIGNATIONS

6005A T4 has the following standard designations and specifications.

Cold Drawn Round/Flat Bars per; 6005A T4, ISO AlSiMg(A), UNI 9006/6, DIN AlMgSi0.7, AFNOR A-GS0.5, UNE L-3454, WNR 3.3210, ASTM B211

Choosing Factors for 6005A T4

- Strength: Mediocre

- Machining: Okay

- Weldability: Very good (Arc welding is the best choice)

- Formability: Average

- Corrosion Resistance: Good

- Heat Treating: Yes

Some Well-Known Applications for 6005A T4

As components of pylons,

Pipelines,

It is also used in interior architectural applications.

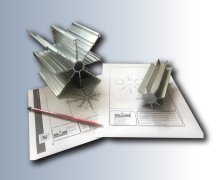

SUPPLIED FORMS

6005A T4 is produced/supplied in plate/sheet round/flat bar and tube/profile forms.

- Rod / Round Bar / Flat Bar

- Tube/Profile

DELIVERY:

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 0.2 up to & incl. 0.5 | 241 | 290 | %8 |

| Over 0.5 up to & incl. 6.5 | 241 | 290 | %10 |

Calculateur de Poids

Calculateur de Poids