Platten

Blech

Rundstangen

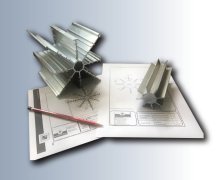

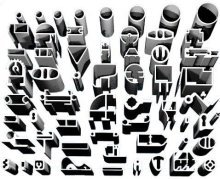

Rohre/ Extrusion/ Profil

3003

AMS QQ-A-250/2 / AlMn1Cu / 3003 / H24

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,60 |

| Manganese (Mn) | 1,00 - 1,50 |

| Copper (Cu) | 0,05 - 0,20 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,73 g/cm³ |

| Melting Point | 582 °C |

| Thermal Expansion | 23.2 µm/m.°C |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 180 W/m.K |

| Electrical Resistivity | 44% IACS |

| Mechanical Properties | Value |

| Proof Strength | 130 MPa |

| Yield Strength | 160 MPa |

| Shear Strength | 93 MPa |

| Elongation A50 mm | 6% |

| Hardness | 45 HB |

3003 H24 aluminum alloy offers high corrosion resistance, excellent formability, and moderate strength. Alloyed with manganese, 3003 is stronger than pure aluminum while maintaining its lightweight and flexible characteristics. The H24 temper indicates that the alloy has been partially strain-hardened but not fully hardened. These properties make 3003 H24 ideal for a variety of applications, such as roofing, containers, kitchen equipment, and cooling systems.

In terms of anodizing, 3003 H24 aluminum alloy has limited suitability. It does not fully possess the structural properties required to create a decorative and effective oxide layer. However, alternative surface treatments like painting or coating can be used to enhance its surface protection and aesthetic appearance. Its weldability is excellent and allows it to be easily joined using standard welding methods, making it versatile for a wide range of uses.

For bending and forming, 3003 H24 aluminum alloy is highly flexible. It is suitable for complex designs and detailed bending processes, with minimal risk of cracking during processing. However, due to its moderate strength, it is not suitable for high-vibration environments. The alloy performs exceptionally well under less stressful conditions and in applications involving light loads.

Regarding corrosion resistance, 3003 H24 aluminum alloy exhibits outstanding durability in humid and corrosive environments. This makes it an excellent choice for outdoor applications, marine equipment, and weather-resistant products. Its advantages include high corrosion resistance, good weldability, and excellent formability, while its disadvantages are limited strength and unsuitability for high-vibration environments. These features make 3003 H24 an ideal material for projects where lightweight, durability, and easy machinability are essential.

Extruded Round/Flat Bar and Tubes per; 3003 H112, AMS QQ-A-200/1, UNS A93003, AFNOR A-M1, UNE L-3810, UNI 9003/1 DIN AlMnCu, WNR 3.0517, ISO AlMn1Cu

Choosing Factors for 3003 H24

- Strength: Moderate

- Machining: Good

- Weldability: Excellent

- Formability: Good

- Corrosion Resistance: Excellent

- Heat Treating: None

Some Well-Known Applications for 3003 H24

I the structure of gutter systems,

In downspouts and roofing applications,

It is also used in storage tanks.

- Sheet

Gewichts-Kalkulator

Gewichts-Kalkulator