3003

AMS 4006 / AlMn1Cu / 3003 / O

| Chemical Properties | % Value |

| Silicon (Si) | 0,40 - 0,80 |

| Chromium (Cr) | 0,04 - 0,35 |

| Manganese (Mn) | 0,00 - 0,15 |

| Magnesium (Mg) | 0,80 - 1,20 |

| Copper (Cu) | 0,15 - 0,40 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,70 g/cm³ |

| Melting Point | 582 °C |

| Thermal Expansion | 23.4 x10^-6 /K |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 170 W/m.K |

| Electrical Resistivity | %43 IACS |

| Mechanical Properties | Value |

| Proof Strength | 310 MPa |

| Yield Strength | 270 MPa |

| Shear Strength | 207 MPa |

| Elongation A50 mm | %15 |

| Hardness | 69 GPa |

6060 T6 is A medium strength aerospace aluminium alloy with, depending upon temper, Yield Strength of up to 35 ksi (240 MPa) and Tensile Strength of 42 ksi (290 MPa)

ALLOY DESIGNATIONS

EN AW 6060 has s imilarities to the following standard designations and specifications ;

Alloy 6060, UNS A96060, ASTM B209 ASTM B221 ASTM B211

EN 4213, 3.3206

TEMPER TYPES

6060 is supplied in a wide range of tempers:

- O - Soft

- T4 - Solution heat treated and naturaly aged to a substantially stable condition

- T5 - Cooled from an elevated temperature shaping process and artificially aged

- T6 - Solution heat treated and artificially aged

- T66 - Solution heat treated then artificially aged by the user

- T6511 - Solution heat treated, stress relieved by stretching then artificially aged

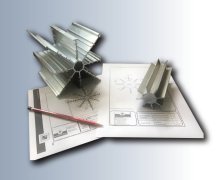

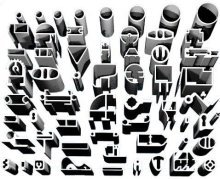

SUPPLIED FORMS

6060 is supplied in plate, bar, round bar, tube, extrusıon and sheet.

- Plate

- Sheet

- Round Bar / Bar

- Tube / Extrusion

DELIVERY:

Gewichts-Kalkulator

Gewichts-Kalkulator