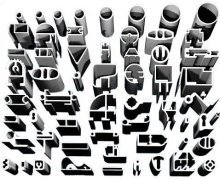

لوحات/ طباقات

صاج

قضيب

أنابيب

7076

ASTM B209 / AlZn6Mg / 7076 / T61

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,10 - 2,90 |

| Copper (Cu) | 1,20 - 2,00 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 5,10 - 6,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.84 g/cm³ |

| Melting Point | 466°C |

| Thermal Expansion | 23.2 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 160 W/m.K |

| Electrical Resistivity | %33 IACS |

| Mechanical Properties | Value |

| Proof Strength | 470 MPa |

| Yield Strength | 510 MPa |

| Shear Strength | 310 MPa |

| Elongation A50 mm | %14 |

| Hardness | 150 HB |

7076 T61 aluminum alloy stands out for its high strength, excellent fatigue resistance, and good thermal stability. As a zinc-based alloy, 7076 is widely used in aerospace, automotive, and defense industries due to its superior mechanical properties. The T61 temper indicates that the alloy has undergone solution heat treatment followed by controlled aging to enhance its strength and durability. This makes it well-suited for load-bearing structures and components operating under demanding conditions.

This alloy is commonly applied in aircraft structures, automotive frames, sports equipment, and other high-performance applications. It is compatible with anodizing, forming a protective oxide layer that improves corrosion resistance while also offering an aesthetic finish. However, due to its high zinc content, anodizing requires careful handling. The weldability of 7076 T61 is limited; its high strength can increase the risk of cracking during welding. Proper processing and the use of suitable filler materials are critical in applications requiring welding.

7076 T61 aluminum alloy has some limitations in formability due to its high strength, making complex shaping processes challenging. Nevertheless, with the right techniques, it can be successfully bent and formed for precision applications. Its exceptional fatigue resistance and mechanical stability make it ideal for use in high-vibration environments, ensuring long-term reliability in components exposed to dynamic loads.

Corrosion resistance is moderate and may require additional surface treatments or coatings when used in highly corrosive environments. Advantages of 7076 T61 include high strength, excellent fatigue resistance, and thermal stability, while its disadvantages include limited weldability, challenging formability, and moderate corrosion resistance. These characteristics make 7076 T61 an excellent material for applications requiring mechanical durability and high performance.

Plates per; 7076 T61, UNS A97076, ASTM B209

Choosing Factors for 7076 T61

- Strength: Excellent

- Machining: Exceptional

- Weldability: Fair

- Formability: Moderate

- Corrosion Resistance: Poor

- Heat Treating: Yes

Some Well-Known Applications for 7076 T61

In propeller blades of helicopters,

In the manufacturing of engine chassis,

It is also used in the aerospace industry where high-stress is required.

SUPPLIED FORMS

- Plate

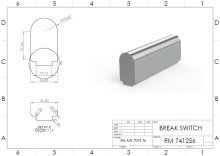

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 0.4 up to & incl. 12.5 | 145 MPa | 275 MPa | %10 |

حساب الوزن

حساب الوزن