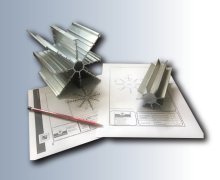

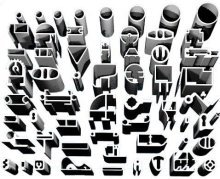

Barras Estiradas en Frío

Tubos Estirados en Frío

6012

Cold Drawn/Finished (CF) / AlMgSiPb (Soğuk Çekim) / 6012 / T6

| Chemical Properties | % Value |

| Silicon (Si) | 0,60 - 1,40 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,40 - 1,00 |

| Magnesium (Mg) | 0,60 - 1,20 |

| Copper (Cu) | 0,60 - 1,10 |

| Titanium (Ti) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Lead (Pb) | 0,40 - 2,00 |

| Physical Properties | Value |

| Density | 2,72 g/cm³ |

| Melting Point | 579 °C |

| Thermal Expansion | 21.7 µm/m-°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | %38 IACS |

| Mechanical Properties | Value |

| Proof Strength | 260 MPa |

| Yield Strength | 320 MPa |

| Shear Strength | 190 MPa |

| Elongation A50 mm | 9% |

| Hardness | 120 HB |

The cold-drawn 6012 T6 aluminum alloy is known for its high strength, excellent machinability, and outstanding corrosion resistance. Widely used in automotive, defense, and machinery manufacturing industries, 6012 T6 is ideal for components requiring both strength and surface quality. This alloy is suitable for anodizing, which enhances surface hardness and provides an aesthetic finish. While it has limited weldability compared to other 6xxx series alloys, welding is possible under suitable conditions. Its high strength after cold drawing also allows it to be bent into complex shapes effectively.

Additionally, 6012 T6 performs well in high-vibration environments, making it a reliable choice for moving parts and vibration-intensive applications. Its corrosion resistance offers protection in harsh environments, while advantages include high machinability, excellent surface quality, and corrosion resistance. On the downside, it has relatively limited weldability compared to other 6xxx alloys and is less ideal for highly flexible applications. The cold-drawn 6012 T6 aluminum alloy is a dependable choice where durability and surface quality are prioritized.

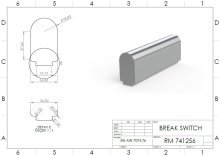

Cold Drawn Round Bars per: 6012 T6, UNS A96013, ASTM B221, ISO AlMg1Si0.8CuMn

Choosing Factors for 6012 T6

- Strength: High

- Machining: Satisfactory

- Weldability: Okay

- Formability: Good

- Corrosion Resistance: Very good

- Heat Treating: Yes

Some Well-Known Applications for 6012 T6

Specifically designed machine parts,

Automotive brake components,

Hydraulic valve blocks.

- Rod / Round Bar

Calculador de Peso

Calculador de Peso