6082

EN AW / AlSi1MgMn / 6082 / O

| Chemical Properties | % Value |

| Silicon (Si) | 0,70 - 1,30 |

| Chromium (Cr) | 0,00 - 0,25 |

| Manganese (Mn) | 0,40 - 1,00 |

| Magnesium (Mg) | 0,60 - 1,20 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 555 °C |

| Thermal Expansion | 24 µm/m°C |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 180 W/m.K |

| Electrical Resistivity | 42 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 85 MPa |

| Yield Strength | 140 MPa |

| Shear Strength | 84 MPa |

| Elongation A50 mm | 18% |

| Hardness | 35 HV |

Aluminium alloy 6082 is a medium to high strength alloy with excellent corrosion resistance. It has the highest strength of the 6000 series alloys. Alloy 6082 is known as a structural alloy. In plate form, 6082 is the alloy most commonly used for machining. As a relatively new alloy, the higher strength of 6082 has seen it replace 6061 in many applications. The addition of a large amount of manganese controls the grain structure which in turn results in a stronger alloy. It is difficult to produce thin walled, complicated extrusion shapes in alloy 6082. The extruded surface finish is not as smooth as other similar strength alloys in the 6000 series.

In the T6 and T651 temper, alloy 6082 machines well and produces tight coils of swarf when chip breakers are used.

In the T6 and T651 temper, alloy 6082 machines well and produces tight coils of swarf when chip breakers are used.

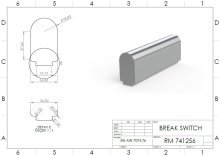

ALLOY DESIGNATIONS

6082 O has the following standard designations and specifications.

As Sheet/Plate; 6082 O, ISO AlSi1MgMn, ASTM B209, UNS A96082, WNR 3.2315,

As Extruded Round/Flat Bar; 6082 O, ISO AlSi1MgMn, ASTM B221, UNS A96082, WNR 3.2315,

As Cold Drawn Round/Flat Bar: 6082 O, ISO AlSi1MgMn, ASTM B211, UNS A96082, WNR 3.2315,

Choosing Factors for 6082 O

- Strength: Mid - high

- Machining: Good

- Weldability: Good

- Formability: Okay

- Corrosion Resistance: Excellent

- Heat Treating: Yes

Some Well-Known Applications for 6082 O

In train wagons, sea boats,

In general, in the transportation sector,

It is also preferred in bridge and ship construction.

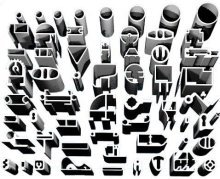

SUPPLIED FORMS

6082 O is produced/supplied in plate/sheet, round/flat bar and tube/profile forms.

- Plate/ Sheet

- Rod / Round Bar / Flat Bar

- Tube/Profile

DELIVERY:

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| 6 - 12,5 | 410 MPa | 460 MPa | |

| 12,5 - 25 | 410 MPa | 460 MPa | |

| 25 - 40 | 400 MPa | 450 MPa | |

| 40 - 63 | 390 MPa | 430 MPa | |

| 63 - 90 | 390 MPa | 430 MPa | |

| 90 - 115 | 370 MPa | 420 MPa | |

| 115 - 140 | 350 MPa | 410 MPa | |

Calculador de Peso

Calculador de Peso