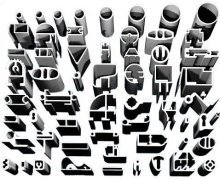

لوحات/ طباقات

صاج

قضيب

أنابيب

7049

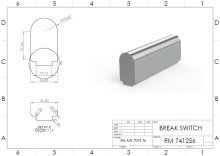

AMS 4200 / AlZn8MgCu / 7049 / T7351

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,25 |

| Chromium (Cr) | 0,10 - 0,22 |

| Manganese (Mn) | 0,00 - 0,50 |

| Magnesium (Mg) | 2,10 - 3,10 |

| Copper (Cu) | 1,20 - 1,90 |

| Titanium (Ti) | 0,00 - 0,25 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 7,20 - 8,40 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.84 g/cm³ |

| Melting Point | 477 °C |

| Thermal Expansion | 23,4 x 10^-6 /K |

| Modulus of Elasticity | 71,7 GPa |

| Thermal Conductivity | 154 W/m.K |

| Mechanical Properties | Value |

| Proof Strength | 517 MPa |

| Yield Strength | 448 MPa |

| Shear Strength | 303 MPa |

| Elongation A50 mm | %12 |

| Hardness | 71,7 GPa |

The 7049 T7351 aluminum alloy is known for its high strength, durability, and excellent mechanical properties. As part of the aluminum-zinc alloy family, it is primarily used in aerospace, space, and high-performance structural applications. The T7351 temper, achieved through specific heat treatments, provides the alloy with high durability and hardness while maintaining machinability. This alloy is not suitable for anodizing due to its high zinc content, which can complicate the anodizing process. In terms of weldability, it requires careful handling as there is an increased risk of cracking during welding. The 7049 T7351 alloy is suitable for bending and forming, though careful processing is needed due to its high strength. It is also suitable for use in high-vibration environments, as its high elastic modulus and durability make it ideal for components such as engine parts and chassis. Corrosion resistance is limited due to its high zinc content, but this can be improved with proper coating and surface treatments. The advantages of the 7049 T7351 alloy include high strength, durability, and lightweight properties, while its disadvantages include limited corrosion resistance and challenges in welding.

ALLOY DESIGNATIONS

7049 T7351 has the following standard designations and specifications.

Plates per; 7049 T7351, AMS 4200, ASTM B209, ISO AlZn8MgCu, AFNOR A-Z8GU, UNS A97049

Choosing Factors for 7049 T7351

- Strength: Perfect

- Machining: High

- Weldability: Low

- Formability: Mediocre

- Corrosion Resistance: Excellent

- Heat Treating: Yes

Some Well-Known Applications for 7049 T7351

In structural forgings,

As a component of missiles in the military industry.

It is also highly used in the aerospace industry.

SUPPLIED FORMS

7049 T7351 is produced/supplied in the plate form.

- Plate

DELIVERY:

حساب الوزن

حساب الوزن