لوحات/ طباقات

صاج

قضيب

أنابيب

7075

AMS 4078 / AlZn5.5MgCu / 7075 / T7351

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Tin (Sn) | 0,00 - 0,00 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,10 - 2,90 |

| Copper (Cu) | 1,20 - 2,00 |

| Lead (Pb) | 0,00 - 0,00 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 5,10 - 6,10 |

| Nickel (Ni) | 0,00 - 0,00 |

| Aluminium (Al) | Balance |

| Titanium + Zirconium (Ti+Zr) | 0,00 - 0,25 |

| Physical Properties | Value |

| Density | 2.81 g/cm³ |

| Melting Point | 477 °C |

| Thermal Expansion | 23 µm/m.°C |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 155 W/m.K |

| Electrical Resistivity | %33 IACS |

| Mechanical Properties | Value |

| Proof Strength | 435 MPa |

| Yield Strength | 510 MPa |

| Shear Strength | 300 MPa |

| Elongation A50 mm | 8% |

| Hardness | 135 HB |

7075 T651 is used in especialy aerospace and many fields.When it will be uses as uniform large plate 7075 T7351 is preferred particularly in large diameters because of insufficient stress corrosion cracking resistance of 7075 T651. In cases where it will be used as uniform aluminum sheet with large dimensions, When used in large dimensions AMS, ASTM selection becomes very important., with this selection 7075 T7351 provides high resistance to both high tensile corrosion and high machinability without distortion problems in perfect precision tolerances. Referans Metal supplied this aluminum material to Turkish Market as first time importing in the market in the year 2006 with The Original Material Supplying method and material used first time for Turkish space industry project.

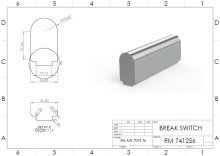

ALLOY DESIGNATIONS

7075 T7351 has similarities to the following standard designations and specifications ;

Plate as; 7075 T7351, AMS QQ-A-250/12, AMS 4078

ASTM B209, AIR 9048-690, WL 3.4364

Cold Drawn Rod,Flat Bar, Wire as; 7075 T7351, AMS QQ-A-225/9,

AMS 4124, ASTM B211

Choosing Factors for 7075 T7351:

- Strength: Good

- Machining: Normal

- Weldability: Poor

- Formability: Weak

- Corrosion Resistance: Significant

- Heat Treating:Yes

Some Well-Known Applications for 7075 T7351:

Chassis construction of medium-sized satellites

Thin-walled discharge designs of very long plates, fixture-turntable projects

Aircraft connection apparatus

In Defence Industry valve-register production at the coating form.

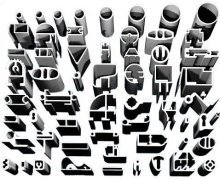

SUPPLIED FORMS

7075 T7351 is supplied in plate, bar / round bar / flat bar and wire form.

- Plate

- Bar / Round Bar / Flat Bar / Wire

DELIVERY:

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| over 6.35 up to & incl. 50.8 | 385 MPa | 468 MPa | 7 |

| over 50.8 up to & incl. 63.5 | 351 MPa | 448 MPa | 7 |

| over 63.5 up to & incl. 76.2 | 331 MPa | 434 MPa | 7 |

حساب الوزن

حساب الوزن