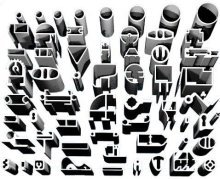

Platten

Blech

Rundstangen

Rohre/ Extrusion/ Profil

7075

QQ-A-250/24 / AlZn5.5MgCu / 7075 / T7651

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Tin (Sn) | 0,00 - 0,00 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,10 - 2,90 |

| Copper (Cu) | 1,20 - 2,00 |

| Lead (Pb) | 0,00 - 0,00 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 5,10 - 6,10 |

| Nickel (Ni) | 0,00 - 0,00 |

| Aluminium (Al) | Balance |

| Titanium + Zirconium (Ti+Zr) | 0,00 - 0,25 |

| Physical Properties | Value |

| Density | 2.81 g/cm³ |

| Melting Point | 480 °C |

| Thermal Expansion | 23 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | %33 IACS |

| Mechanical Properties | Value |

| Proof Strength | 470 MPa |

| Yield Strength | 550 MPa |

| Shear Strength | 320 MPa |

| Elongation A50 mm | %8 |

| Hardness | 150 HB |

Although 7075 T7651 Plate has similar mechanical values to 7075 T651, tensile corrosion resistance is increased compared to T651 and it is an aluminum alloy which is produced more resistant to exfoliation corrosion. It is preferred in thick plates. It is mostly preferred in expensive projects due to its long life time.

ALLOY DESIGNATIONS

7075 T7651 has similarities to the following standard designations and specifications ;

Plate and Sheet as; 7075 T7651, AMS QQ-A-250/24,

ASTM B209, AIR 9048-710

Choosing Factors for 7075 T7651:

- Strength: Very good

- Machining: Excellent

- Weldability: Weak

- Formability: Poor

- Corrosion Resistance: Significant

- Heat Treating:Yes

TEMPER TYPES

AMS QQ-A-250/24 7075 is supplied in the following heat treatment types:

- T7651

Some Well-Known Applications for 7075 T7651:

In aerospace parts Which subject to high strength and stress

Special Fuel Tanks

Ship industry

SUPPLIED FORMS

7075 T7651 is supplied in plate and sheet form.

- Plate

- Sheet

DELIVERY:

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| over 12.7 up to & incl. 25.4 | 410 MPa | 486 MPa | 6 |

| over 6.35 up to & incl. 12.7 | 418 MPa | 491 MPa | 8 |

Gewichts-Kalkulator

Gewichts-Kalkulator