Platten

Blech

Rundstangen

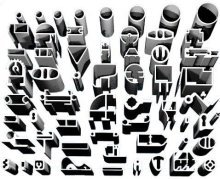

Rohre/ Extrusion/ Profil

7040

AMS 4211 / AlZn6Mg2Cu2 / 7040 / T7451

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,10 |

| Chromium (Cr) | 0,00 - 0,04 |

| Manganese (Mn) | 0,00 - 0,04 |

| Magnesium (Mg) | 1,90 - 2,40 |

| Copper (Cu) | 1,50 - 2,30 |

| Titanium (Ti) | 0,00 - 0,06 |

| Iron (Fe) | 0,00 - 0,13 |

| Zinc (Zn) | 5,70 - 6,70 |

| Aluminium (Al) | Balance |

| Titanium + Zirconium (Ti+Zr) | 0,05 - 0,12 |

| Physical Properties | Value |

| Density | 2.85 g/cm³ |

| Mechanical Properties | Value |

| Proof Strength | 400 MPa |

| Yield Strength | 450 MPa |

| Elongation A50 mm | 7% |

Alloy 7040 is a variation of 7050, where Zr additions prevent recrystallization of hot-worked products during solution heat treatment without the quench sensitivity from additions of Cr.

7040-T7451 plates deliver an improved strength toughness balance compared to 7010 and 7050 alloys, and are ideal for structures needing high strength, high toughness, and good corrosion resistance, such as integrally machined spars, ribs, fuselage frames or other thick sections.

Choosing Factors for 7040 T7451

- Strength: Very good

- Machining: Satisfactory

- Weldability: Weak

- Formability: Fair

- Corrosion Resistance: Good

- Heat Treating: Yes

Some Well-Known Applications for 7040 T7451

Mainly in the aerospace industry,

As fuselage components,

And it is also used in cockpit window frames.

- Plate

Gewichts-Kalkulator

Gewichts-Kalkulator