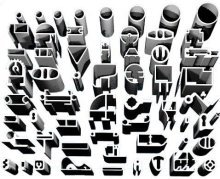

Platos

Hojas

Barras Circulares

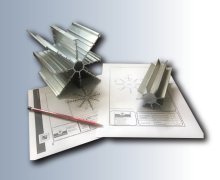

Tubos / Extrusion / Perfil

7475

AMS 4089 / AlZn5.5MgCu / 7475 / T7651

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,10 |

| Chromium (Cr) | 0,18 - 0,25 |

| Manganese (Mn) | 0,00 - 0,06 |

| Magnesium (Mg) | 1,90 - 2,60 |

| Copper (Cu) | 1,20 - 1,90 |

| Titanium (Ti) | 0,00 - 0,06 / - |

| Iron (Fe) | 0,00 - 0,12 |

| Zinc (Zn) | 5,20 - 6,20 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,81 g/cm³ |

| Melting Point | 477 °C |

| Thermal Expansion | 23 µm/m.°C |

| Modulus of Elasticity | 71.7 GPa |

| Thermal Conductivity | 163 W/m.K |

| Electrical Resistivity | %33 IACS |

| Mechanical Properties | Value |

| Proof Strength | 460 MPa |

| Yield Strength | 540 MPa |

| Shear Strength | 320 MPa |

| Elongation A50 mm | 11% |

| Hardness | 140 HB |

The 7475 T7651 aluminum alloy has almost the same or only slightly lower resistance to stress corrosion cracking than 7475 T651, However, 7475 T7651 aluminum is produced for very high levels of exfoliation corrosion resistant.

ALLOY DESIGNATIONS

AMS 4089 7475 T7651 has similarities to the following standard designations and specifications ;

Plate as; 7475 T7651, AIR 9048-730, EN 2805,

Sheet as; 7475 T7651, AMS STD 2154, AMS 4085

Alloy 7475, UNS A97475

AlZn5.5MgCu,

Choosing Factors for 7475 T7651:

- Strength: Excellent

- Machining: Very good

- Weldability: Low

- Formability: Poor

- Corrosion Resistance: Average

- Heat Treating:Yes

TEMPER TYPES

AMS 4089 7475 is supplied in the following heat treatment types:

- T7651

Some Well-Known Applications for 7475 T7651:

Jet aircraft

Energy production systems.

Petrochemical plants and raw material extraction units ..

SUPPLIED FORMS

7475 T7651 is supplied in plate and sheet form.

- Plate

- Sheet

DELIVERY:

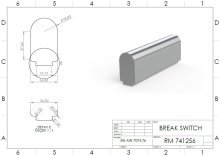

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| over 6.0 up to & incl. 50 | 440 MPa | 515 MPa | 10 |

Calculador de Peso

Calculador de Peso