Dalle

Tôle

Barre ronde

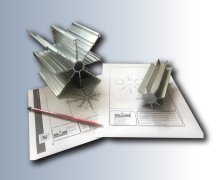

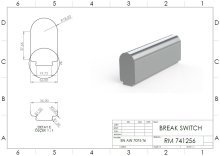

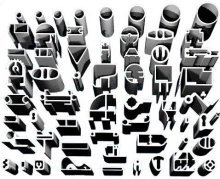

Tube/ Extrusion/ Profil

1060

AMS 4000 / Al99.6 / 1060 / O

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,25 |

| Manganese (Mn) | 0,00 - 0,03 |

| Magnesium (Mg) | 0,00 - 0,03 |

| Copper (Cu) | 0,00 - 0,05 |

| Titanium (Ti) | 0,00 - 0,03 |

| Iron (Fe) | 0,00 - 0,35 |

| Zinc (Zn) | 0,00 - 0,05 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.705 g/cm³ |

| Melting Point | 646 °C |

| Thermal Expansion | 22.8 µm/m°C |

| Modulus of Elasticity | 73 GPa |

| Thermal Conductivity | 155 W/m.K |

| Electrical Resistivity | 62 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 21 MPa |

| Yield Strength | 75 MPa |

| Shear Strength | 49 MPa |

| Elongation A50 mm | 30% |

| Hardness | 19 HB |

1060 O aluminum alloy is an aluminum-based alloy in the "commercially pure" wrought family. As a wrought alloy, it is typically formed by extrusion or rolling. It is commonly used in the electrical and chemical industries, on account of having high electrical conductivity, corrosion resistance, and workability.

ALLOY DESIGNATIONS

1060 O has the following standard designations and specifications.

Sheets per; 1060 O, ASTM B209, UNS A91060, ISO Al99.6

Extruded Round/Flat Bar, Wire and Tubes per; 1060 O, ASTM B221, ASTM B491, ISO Al99.6

Cold Drawn Round/Flat Bar, Wire and Tubes per; 1060 O, ASTM B211, ISO Al99.6

Choosing Factors for 1060 O

- Strength: Moderate

- Machining: Poor

- Weldability: Excellent

- Formability: Perfect

- Corrosion Resistance: Very good

- Heat Treating: Yes

Some Well-Known Applications for 1060 O

It is also used in billboard frames/decorations,

Kitchen utensils, wares

and as a component of railway tracks.

SUPPLIED FORMS

1060 O is produced/supplied in sheet, round/flat bar and tube/profile forms.

- Sheet

- Round/Flat Bar

- Tube/Profile

DELIVERY:

Calculateur de Poids

Calculateur de Poids