Листы/Плиты

Лист

Бар/Листовая Сталь

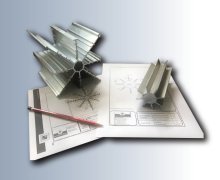

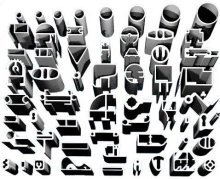

Трубы/Профили

2014 clad

ASTM B209 / AlCu4SiMg / 2014 clad / O

| Chemical Properties | % Value |

| Silicon (Si) | 0,5 - 1,2 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,40 - 1,20 |

| Magnesium (Mg) | 0,20 - 0,80 |

| Copper (Cu) | 3,90 - 5,00 |

| Titanium (Ti) | 0,00 - 0,15 / 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.80 g/cm³ |

| Melting Point | 507 °C |

| Thermal Expansion | 22.7 µm/m°C |

| Modulus of Elasticity | 73 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | 40 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 100 MPa |

| Yield Strength | 190 MPa |

| Shear Strength | 130 MPa |

| Elongation A50 mm | %17 |

| Hardness | 48 HB |

Alclad 2014 O aluminum alloy is known for its high strength, good machinability, and excellent corrosion resistance. Alclad is a version of the 2014 O alloy that is coated with a thin layer of pure aluminum on its surface to enhance its corrosion resistance. This feature makes Alclad 2014 O suitable for use in high-durability applications in environments that are sensitive to corrosion. As part of the aluminum-copper alloy family, it is widely used in aerospace and space industries for high-performance structural components.

The Alclad 2014 O aluminum alloy has limited suitability for anodizing. The pure aluminum layer provides a protective oxide layer, improving corrosion resistance, but the copper content in the core alloy prevents the formation of an effective oxide layer during anodizing, making anodizing difficult for the alloy. In terms of weldability, Alclad 2014 O performs well due to its high purity, enabling strong and reliable welds when proper welding techniques are used. However, due to its copper content, special care is needed during welding to avoid cracking.

In terms of bending and forming, Alclad 2014 O aluminum alloy is highly flexible and easy to shape. This characteristic makes it advantageous for producing complex shapes in industries such as aerospace, automotive, and construction. However, despite its high strength, Alclad 2014 O is generally not suitable for high-vibration environments. It is better suited for low-vibration and low-load applications.

Regarding corrosion resistance, Alclad 2014 O exhibits high durability due to the pure aluminum layer on its surface. However, the copper content in the alloy limits its overall corrosion resistance compared to other aluminum alloys. These limitations can be overcome with proper coatings and surface treatments. The advantages of Alclad 2014 O include high strength, good machinability, and improved corrosion resistance, while its disadvantages include limited corrosion resistance in certain conditions and challenges in welding.

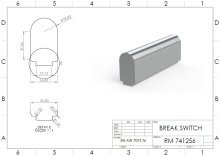

As Alclad sheet; 2014 O clad, ASTM B209, ISO AlCu4SiMg, UNS A92014, WNR 3.1255

Choosing Factors for 2014 O clad

- Strength: Exquisite

- Machining: Great

- Weldability: Weak

- Formability: Good

- Corrosion Resistance: Poor

- Heat Treating: Yes

Some Well-Known Applications for 2014 O clad

In the aerospace sector,

In pipelines, oil refineries,

It is used in power plants and the automotive industry.

- Sheet

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 1.02 up to & incl. 6.32 | 235 MPa | 395 MPa | %15 |

| Over 12.7 up to & incl. 6.32 | 235 MPa | 400 MPa | %15 |

Калькулятор Веса

Калькулятор Веса