Cold Drawn Round Bar

Cold Drawn Tube

7075

Cold Drawn/Finished (CF) / AlZn5.5MgCu (Soğuk Çekim) / 7075 / T6

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,10 - 2,90 |

| Copper (Cu) | 1,20 - 2,00 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 5,10 - 6,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.81 g/cm³ |

| Melting Point | 466 °C |

| Thermal Expansion | 23.4 µm/m.°C |

| Modulus of Elasticity | 71.7 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | %33 IACS |

| Mechanical Properties | Value |

| Proof Strength | 480 MPa |

| Yield Strength | 560 MPa |

| Shear Strength | 330 MPa |

| Elongation A50 mm | %7 |

| Hardness | 140 HB |

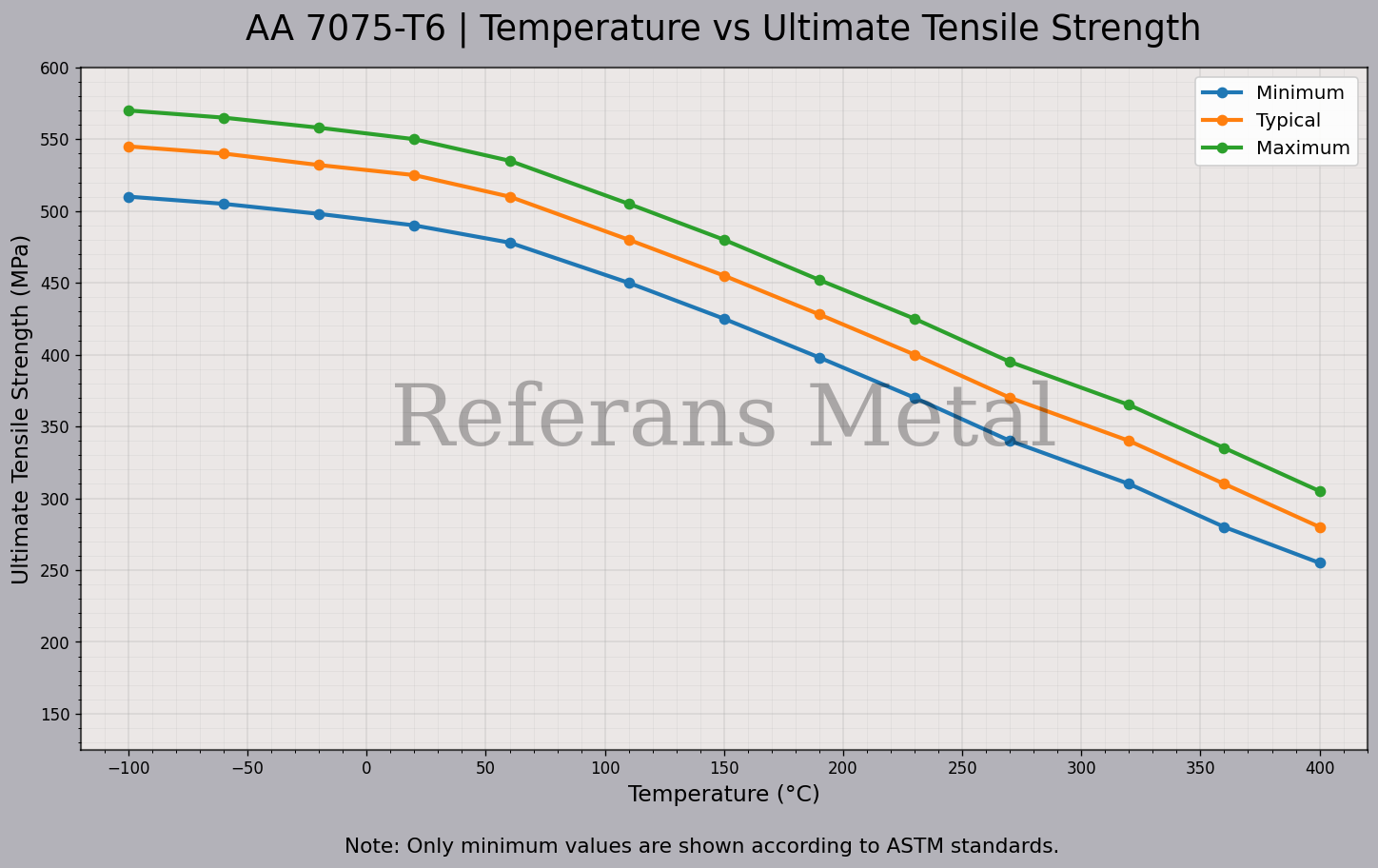

| 7075 T6 Temperature – Tensile Strength Graph |

|

7075 T6 aluminum alloy belongs to the Al-Zn-Mg-Cu (7xxx series) group and is one of the highest-strength aluminum alloys available. The T6 temper condition, achieved through solution heat treatment followed by artificial aging, allows the alloy to reach its maximum strength level. As a result, 7075 T6 exhibits significantly higher tensile and yield strength compared to 6xxx series alloys such as 6082 and 6061. However, as a consequence of this high strength, its corrosion resistance is more limited, especially in marine and aggressive environments, and surface protection is generally required.

(2).png) In terms of machinability, 7075 T6 performs very well. High surface quality can be achieved during machining operations, and despite its hardness, cutting processes can be carried out in a controlled manner. On the other hand, its bending and cold forming capability is low; due to the hard T6 temper, there is a high risk of cracking during forming. In this respect, 7075 T6 falls behind more formable alloys such as 6082 T4 or 6063. Regarding vibration behavior, its high elastic modulus provides a rigid structure, but its vibration damping capacity is more limited compared to steel and some more ductile aluminum alloys.

In terms of machinability, 7075 T6 performs very well. High surface quality can be achieved during machining operations, and despite its hardness, cutting processes can be carried out in a controlled manner. On the other hand, its bending and cold forming capability is low; due to the hard T6 temper, there is a high risk of cracking during forming. In this respect, 7075 T6 falls behind more formable alloys such as 6082 T4 or 6063. Regarding vibration behavior, its high elastic modulus provides a rigid structure, but its vibration damping capacity is more limited compared to steel and some more ductile aluminum alloys.

One of the main drawbacks of 7075 T6 alloy is its poor weldability. Due to the risk of hot cracking during welding and significant loss of strength after welding, this alloy is generally not recommended for welded applications. In this aspect, it is disadvantaged compared to alloys such as 5083 and 6082, which are suitable for MIG and TIG welding. In terms of surface finishing, 7075 T6 is suitable for anodizing and painting; however, due to its copper content, the anodized surface appearance may be less uniform. Therefore, functional surface treatments are preferred over decorative applications.

Thanks to its very high strength-to-weight ratio, 7075 T6 is widely used in the aerospace and aviation industries, defense industry, racing and high-performance automotive components, tooling and fixture manufacturing, and machine parts subjected to high loads. While it offers strength levels comparable to 2024 alloy in aerospace applications, 7075 T6 is generally preferred for critical components requiring higher strength. Overall, despite its limited formability and weldability, 7075 T6 remains an indispensable aluminum alloy for performance-driven and safety-critical applications due to its exceptional strength.

MATERIAL COMPOSITION STANDARDS

7075 T6 can conform to the following standards:

• 7075 T6 Sheet; AMS QQ-A-250/12, AMS 4045, ASTM B209, EN 2696

• 7075 T6 Alclad Sheet; AMS QQ-A-250/13, AMS 4049, ASTM B209, AIR 9048-280, BS 2 L88, WL 3.4374, DAN 424, EN 2092

• 7075 T6 Oneside Alclad Sheet; AMS QQ-A-250/18, AMS 4046, ASTM B209

• 7075 T6 Extrusion Seamless Tube; AMS QQ-A-200/11, AMS 4154, ASTM B241

• 7075 T6 Extrusion Rod; AMS QQ-A-200/11, AMS 4154, ASTM B221

• 7075 T6 Extrusion Flat Bar; AMS QQ-A-200/11, AMS 4154, ASTM B221

• 7075 T6 Extrusion Wire; AMS QQ-A-200/11, AMS 4154, ASTM B221

• 7075 T6 Cold Drawn Rod; AMS QQ-A-225/9, AMS 4122, ASTM B211

• 7075 T6 Cold Drawn Flat Bar; AMS QQ-A-225/9, AMS 4122, ASTM B211

• 7075 T6 Cold Drawn Wire; AMS QQ-A-225/9, AMS 4122, ASTM B211

• 7075 T6 Cold Drawn Seamless Tube; AMS-T-700/7, ASTM B210

Alloy 7075, UNS A97075, AlZn5.5MgCu, DIN 3.4365, A-Z5GU

Characteristic Properties of 7075 T6:

- Strength: Excellent

- Machinability: Good

- Weldability: Poor

- Formability: Moderate

- Corrosion Resistance: Low

- Heat Treatment: Yes

Some Well-Known Applications of 7075 T6:

Used in many places from supersonic aircraft to sewing machine equipment.

Shoe injection molds, nuclear reactors.

In hundreds of industries as coils, springs, flanges.

STOCK

7075 T6 is supplied in sheet, rod, and flat bar forms.

- Sheet

- Rod / Flat Bar

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| over 0.203 up to & incl. 0.279 | 430 MPa | 505 MPa | 5 |

| over 0.305 up to & incl. 0.991 | 458 MPa | 520 MPa | 7 |

| over 1.02 up to & incl. 3.17 | 465 MPa | 535 MPa | 8 |

| over 3.20 up to & incl. 6.32 | 472 MPa | 533 MPa | 8 |

| over 6.35 up to & incl. 12.7 | 459MPa | 534 MPa | 9 |

| over 12.7 up to & incl. 25.4 | 465 MPa | 538 MPa | 7 |

| over 25.43 up to & incl. 50.8 | 457 MPa | 526 MPa | 6 |

| over 50.83 up to & incl. 63.5 | 437 MPa | 519 MPa | 5 |

| over 63.53 up to & incl. 76.2 | 417 MPa | 491 MPa | 5 |

| over 76.23 up to & incl. 88.9 | 394 MPa | 485 MPa | 5 |

| over 88.93 up to & incl. 102 | 368 MPa | 458 MPa | 4 |

Weight Calculator

Weight Calculator