Листы/Плиты

Лист

Бар/Листовая Сталь

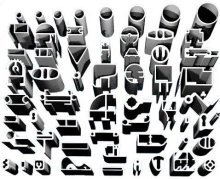

Трубы/Профили

2219

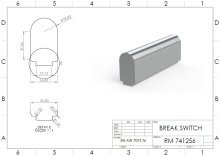

AMS 4162 / AlCu6Mn / 2219 / T8511

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,20 |

| Manganese (Mn) | 0,20 - 0,40 |

| Magnesium (Mg) | 0,00 - 0,02 |

| Copper (Cu) | 5,80 - 6,80 |

| Titanium (Ti) | 0,02 - 0,10 |

| Iron (Fe) | 0,00 - 0,30 |

| Zinc (Zn) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.84 g/cm³ |

| Melting Point | 543 °C |

| Thermal Expansion | 22 µm/m°C |

| Modulus of Elasticity | 74 GPa |

| Thermal Conductivity | 120 W/m.K |

| Electrical Resistivity | %30 IACS |

| Mechanical Properties | Value |

| Proof Strength | 330 MPa |

| Yield Strength | 430 MPa |

| Shear Strength | 270 MPa |

| Elongation A50 mm | 8% |

| Hardness | 110 HB |

The 2219 T8511 aluminum alloy is known for its high mechanical strength, excellent corrosion resistance, and good machinability. The T8511 temper, achieved through heat treatment, gives the alloy high hardness and durability. These characteristics make 2219 T8511 ideal for high-performance applications, particularly in industries such as aerospace, defense, and space. Additionally, 2219 T8511 is suitable for anodizing, which enhances its surface appearance while improving corrosion resistance, making it perfect for long-lasting use in harsh environments like outdoor and maritime applications.

In terms of weldability, 2219 T8511 aluminum alloy can be successfully welded with proper techniques. However, due to its high hardness and strength, welding requires careful handling. The alloy's high hardness also requires specific heat treatment during the welding process. Regarding bending, 2219 T8511 is more difficult to bend compared to more flexible alloys due to its hardness. However, with the appropriate machinery and techniques, it can still be shaped, though extra care is needed during the process.

The corrosion resistance of 2219 T8511 is excellent, especially in aggressive environments like seawater. This makes it ideal for maritime and outdoor structural applications. Additionally, 2219 T8511 is suitable for use in high-vibration environments, making it advantageous for industries such as aerospace, automotive, and defense. Its durability and long-lasting performance increase the reliability of 2219 T8511 in demanding applications.

The advantages of 2219 T8511 aluminum alloy include high mechanical strength, excellent corrosion resistance, anodizing compatibility, weldability, and suitability for high-vibration environments. However, its high hardness and strength can create challenges during welding and bending processes. Furthermore, this alloy may not be as easy to machine as more flexible alloys. Despite these challenges, 2219 T8511 remains an excellent choice for industrial applications requiring high performance and durability.

As Extruded Round/Flat Bar, Tube ; 2219 T8511, ASTM B221, UNS A92219, AMS 4162, ISO AlCu6Mn

Choosing Factors for 2219 T8511

- Strength: Very good

- Machining: Poor

- Weldability: Great

- Formability: Good

- Corrosion Resistance: High

- Heat Treating: Yes

Some Well-Known Applications for 2219 T8511

In weldaments requiring high strength,

In bicycle frames and engineering applications in general,

It has many uses, including camping equipment.

- Round Bar

- Tube

Калькулятор Веса

Калькулятор Веса