Листы/Плиты

Лист

Бар/Листовая Сталь

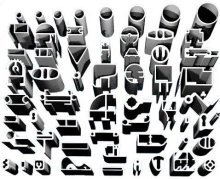

Трубы/Профили

2219

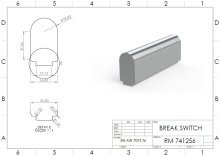

AMS 4295D / AlCu6Mn / 2219 / T37

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,20 |

| Manganese (Mn) | 0,20 - 0,40 |

| Magnesium (Mg) | 0,00 - 0,02 |

| Copper (Cu) | 5,80 - 6,80 |

| Titanium (Ti) | 0,02 - 0,10 |

| Iron (Fe) | 0,00 - 0,30 |

| Zinc (Zn) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.84 g/cm³ |

| Melting Point | 535 °C |

| Thermal Expansion | 22.3 µm/m.°C |

| Modulus of Elasticity | 73.1 GPa |

| Thermal Conductivity | 112 W/m.K |

| Electrical Resistivity | 30% IACS |

| Mechanical Properties | Value |

| Proof Strength | 317 MPa |

| Yield Strength | 393 MPa |

| Shear Strength | 255 MPa |

| Elongation A50 mm | 8% |

| Hardness | 117 HB |

2219 T37 aluminum alloy is known for its high strength, excellent weldability, and thermal durability. As part of the aluminum-copper alloy family, this material is enhanced through the T37 temper, which involves heat treatment and mechanical processing to achieve moderate hardness and flexibility. Its ability to perform well under high temperatures makes 2219 T37 ideal for structural components used in challenging environments such as aerospace and space applications.

In terms of anodizing, the 2219 T37 aluminum alloy has limited suitability. Its copper content can inhibit the formation of an effective oxide layer, reducing the efficiency of the anodizing process. Therefore, alternative coating methods are often employed to protect the surface. However, when it comes to weldability, the 2219 T37 alloy performs exceptionally well. With proper welding techniques and suitable filler materials, strong and durable joints can be achieved while minimizing the risk of cracking.

For bending and forming, the 2219 T37 aluminum alloy offers moderate formability. Due to its strength, careful handling is required during bending processes. It is highly suitable for use in high-vibration environments thanks to its elastic modulus and durability. These characteristics make it an excellent choice for aircraft structures, engine components, and other structural parts exposed to significant vibration.

In terms of corrosion resistance, the 2219 T37 aluminum alloy is somewhat limited compared to other aluminum alloys due to its copper content. However, this drawback can be mitigated with appropriate surface treatments and coating techniques. Its advantages include high-temperature resistance, excellent weldability, and durability, while its disadvantages are limited corrosion resistance and lower suitability for anodizing. These features make 2219 T37 an ideal material for projects where strength and thermal durability are critical.

As Alclad Sheet/Plate; 2219 T37, ASTM B209, UNS A92219, ISO AlCu6Mn, AMS 4295D

Choosing Factors for 2219 T37

- Strength: Great

- Machining: Poor

- Weldability: Very good

- Formability: Good

- Corrosion Resistance: Significant

- Heat Treating: Yes

Some Well-Known Applications for 2219 T37

In rocket engine boosters, fuel tanks,

In the engine frame of airplanes and rockets,

It is used in high-strength engineering applications and generally in the aerospace sector.

- Sheet

- Plate

Калькулятор Веса

Калькулятор Веса