Dalle

Tôle

Barre ronde

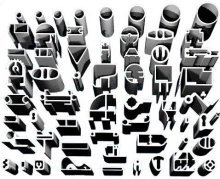

Tube/ Extrusion/ Profil

5052

AMS 4015 / AlMg2.5 / 5052 / O

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,25 |

| Chromium (Cr) | 0,15 - 0,35 |

| Manganese (Mn) | 0,00 - 0,10 |

| Magnesium (Mg) | 2,20 - 2,80 |

| Copper (Cu) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,40 |

| Zinc (Zn) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.68 g/cm³ |

| Melting Point | 607 °C |

| Thermal Expansion | 23.8 µm/m.°C |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 138 W/m.K |

| Electrical Resistivity | %35 IACS |

| Mechanical Properties | Value |

| Proof Strength | 89.6 MPa |

| Yield Strength | 193 MPa |

| Shear Strength | 124 MPa |

| Elongation A50 mm | 22% |

| Hardness | 47 HB |

5052 O aluminum alloy offers excellent corrosion resistance, good weldability, and outstanding formability. Alloyed with magnesium, 5052 stands out for its combination of high durability and lightweight properties. The O temper indicates that the alloy is annealed and in a soft state, providing advantages in flexibility and workability. These characteristics make 5052 O ideal for various applications, including marine equipment, fuel tanks, chemical containers, and aerospace components.

In terms of anodizing, 5052 O aluminum alloy is highly suitable. It forms a smooth oxide layer on the surface, enhancing corrosion resistance and providing an aesthetically pleasing finish. This makes it particularly advantageous for decorative products and outdoor applications. Regarding weldability, 5052 O performs exceptionally well and can be easily joined using standard methods like MIG or TIG welding. It retains much of its structural integrity after welding, making it ideal for structural applications.

When it comes to bending and forming, 5052 O aluminum alloy is extremely flexible. It is well-suited for creating complex shapes and tight-radius bends. It is also a good choice for high-vibration environments due to its fatigue resistance and durability, ensuring reliable performance over time. Additionally, its lightweight and strength make it advantageous for easy handling and durability.

In terms of corrosion resistance, 5052 O aluminum alloy demonstrates excellent durability in humid, marine, and chemical environments. However, in applications requiring high mechanical strength, the soft temper of the alloy may present a limitation. Its advantages include high corrosion resistance, excellent formability, and good weldability, while its disadvantages include limited mechanical strength and sensitivity to high temperatures. These properties make 5052 O an excellent material for projects requiring durability, lightweight, and exceptional formability.

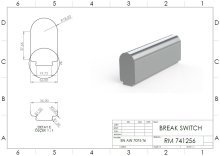

Sheets and Plates per; 5052 O, AMS 4015, AMS QQ-A-250/8, ISO AlMg2.5, WNR 3.3523, UNS A95052, ASTM B209

Extruded Round/Flat Bar and Wires; 5052 O, ISO AlMg2.5, WNR 3.3523, UNS A95052, ASTM B221

Seamless Cold Drawn Tube; 5052 O, ASTM B210, AMS 4069 (Close tolerance), AMS 4070, AMS 4071 (Hydraulic tube), WW-T-700/4, ISO AlMg2.5, WNR 3.3523, UNS A95052

Choosing Factors for 5052 O

- Strength: Moderate

- Machining: Okay

- Weldability: High

- Formability: Satisfactory

- Corrosion Resistance: Excellent

- Heat Treating: None

Some Well-Known Applications for 5052 O

In marine applications,

Architectural facade design and construction,

Also used in electronic circuits.

- Tube/Profile

- Plate

- Sheet

- Round/Flat Bar

Calculateur de Poids

Calculateur de Poids