板/板

钣金

棒条/金属板

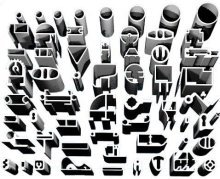

管道/型材

5456

ASTM B209 / AlMg5Mn1 / 5456 / H116

| 化学性质 | % 值 |

| Silicon (Si) | 0,00 - 0,25 |

| Chromium (Cr) | 0,05 - 0,20 |

| Manganese (Mn) | 0,50 - 1,00 |

| Magnesium (Mg) | 4,70 - 5,50 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,40 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| 物理特性 | 值 |

| Density | 2,66 g/cm³ |

| Melting Point | 568 °C |

| Thermal Expansion | 23.9 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 116 W/m-K |

| Electrical Resistivity | 29 % IACS |

| 机械性能 | 值 |

| Proof Strength | 240 MPa |

| Yield Strength | 352 MPa |

| Shear Strength | 207 MPa |

| Elongation A50 mm | 13% |

| Hardness | 90 HB |

5456 H116 aluminum alloy is known for its exceptional strength, excellent corrosion resistance, and high fatigue durability. As a magnesium-based alloy, 5456 is designed to perform in harsh environments, particularly in the marine and defense industries. The H116 temper indicates that the alloy has been mechanically hardened and stabilized for use in corrosive environments, such as seawater. These characteristics make it an ideal choice for projects that demand durability and reliability.

5456 H116 is widely used in applications such as shipbuilding, offshore platforms, fuel tanks, military armor systems, and pressure vessels. It is highly suitable for anodizing, which enhances corrosion resistance while providing an aesthetically pleasing finish. The alloy also exhibits excellent weldability and can be easily joined using standard techniques like MIG or TIG welding. After welding, it retains much of its strength, making it a reliable material for structural applications.

In terms of bending and forming, 5456 H116 aluminum alloy is suitable for creating complex shapes despite its high strength. While it requires careful handling during processing, proper techniques yield successful results. The alloy's excellent fatigue resistance makes it ideal for use in high-vibration environments. It provides long-term durability for equipment and structures exposed to dynamic loads, ensuring reliable performance in challenging conditions.

The corrosion resistance of 5456 H116 is one of its most notable features. It demonstrates exceptional durability against saltwater, humid environments, and chemicals, making it a perfect choice for marine and outdoor applications. However, it may have limitations in applications requiring extremely high strength or bearing excessive loads. Advantages include high corrosion resistance, excellent weldability, good formability, and fatigue resistance, while disadvantages include the need for careful processing and limited load-bearing capacity. These attributes make 5456 H116 an ideal material for projects where lightweight and durability are critical.

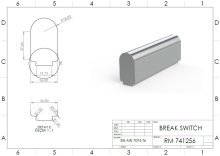

Sheets and plates per; 5456 H116, ISO AlMg5Mn1, ASTM B928, ASTM B209, AMS QQ-A-250/9, UNS A95456, MIL-A-19842C

Choosing Factors for 5456 H116

- Strength: High

- Machining: Weak

- Weldability: Very good

- Formability: Poor

- Corrosion Resistance: Excellent

- Heat Treating: None

Some Well-Known Applications for 5456 H116

In architectural applications,

In parts of air conditioners and coolers,

It is also used in overhead cranes.

SUPPLIED FORMS

- Sheet

- Plate

计算 重量计算

计算 重量计算