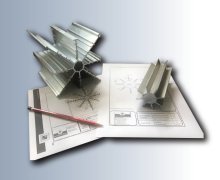

Листы/Плиты

Лист

Бар/Листовая Сталь

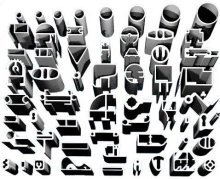

Трубы/Профили

6061

AMS 4025 / AlMg1SiCu / 6061 / O

| Chemical Properties | % Value |

| Silicon (Si) | 0,40 - 0,80 |

| Chromium (Cr) | 0,04 - 0,35 |

| Manganese (Mn) | 0,00 - 0,15 |

| Magnesium (Mg) | 0,80 - 1,20 |

| Copper (Cu) | 0,15 - 0,40 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 582 °C |

| Thermal Expansion | 23.6 µm/m.°C |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 170 W/m.K |

| Electrical Resistivity | 46.5 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 76 MPa |

| Yield Strength | 124 MPa |

| Shear Strength | 84 MPa |

| Elongation A50 mm | %20 |

| Hardness | 33 HB |

6061 O aluminum alloy is well-known for its good strength, excellent corrosion resistance, and high machinability. Alloyed with magnesium and silicon, 6061 combines durability and formability while maintaining its lightweight properties. The O temper indicates that the material is in an annealed state with a soft structure, making it highly suitable for bending and forming processes.

6061 O aluminum alloy is widely used in automotive, aerospace, marine, and general industrial applications. It is also preferred for components such as pipes, containers, and intricate parts that require precise machining. It is highly suitable for anodizing, forming a smooth oxide layer that enhances its aesthetic appearance and corrosion resistance. Additionally, it exhibits excellent weldability and can be easily joined using standard techniques like MIG or TIG welding, maintaining much of its structural integrity after welding.

In terms of bending and forming, 6061 O aluminum alloy stands out for its flexibility. It is ideal for complex designs and tight-radius bends. It also performs well in high-vibration environments due to its fatigue resistance and mechanical stability, ensuring long-term durability. These characteristics make it a reliable choice for structures subjected to dynamic loads and vibrations.

The corrosion resistance of 6061 O is one of its strongest features. It demonstrates excellent durability in saltwater, humid environments, and exposure to chemicals. However, due to its soft temper, its performance may be limited in applications requiring very high strength. Its advantages include high corrosion resistance, excellent weldability, formability, and anodizing compatibility, while its disadvantages include limited load-bearing capacity. These features make 6061 O an ideal material for projects prioritizing lightweight, durability, and workability.

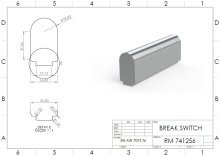

As Plate/Sheet; 6061 O, AMS 4025, AMS QQ-A-250/11, EN 2694, AIR 9048.210/230, UNS A96061, WNR 3.3211, ASTM B209

As Cold Drawn Round/Flat Bar and Tube; 6061 O, AMS 4115, BACM 171, UNS A96061, WNR 3.3211, ISO AlMg1SiCu, ASTM B211

As Seamless Cold Drawn Round/Flat Bar and Tube; 6061 O, AMS 4079 (Close tolerance), AMS 4080, UNS A96061, WNR 3.3211, ISO AlMg1SiCu, ASTM B241

As Extruded Round/Flat Bar and Tube; 6061 O, AMS 4160, UNS A96061, WNR 3.3211, ISO AlMg1SiCu, ASTM B221

Choosing Factors for 6061 O

- Strength: Average

- Machining: Fair

- Weldability: Very good

- Formability: Good

- Corrosion Resistance: Great

- Heat Treating: Yes

Some Well-Known Applications for 6061 O

It has many uses, including transportation, recreational products,

Pipelines and aircraft parts,

And in general, the aerospace industry.

- Rod / Round Bar / Flat Bar

- Plate

- Sheet

- Tube/Profile

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 0.2 up to & incl. 0.5 | 83 | 152 | %14 |

| Over 0.5 up to & incl. 3.2 | 83 | 152 | %16 |

| Over 3.2 up to & incl. 12.8 | 83 | 152 | %18 |

Калькулятор Веса

Калькулятор Веса