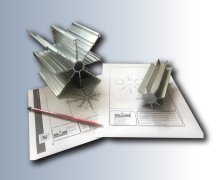

Dalle

Tôle

Barre ronde

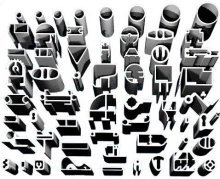

Tube/ Extrusion/ Profil

7075 Alclad

QQ-A-250/13 / AlZn5.5MgCu / 7075 Alclad / T62

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,10 - 2,90 |

| Copper (Cu) | 1,20 - 2,00 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 5,10 - 6,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.81 g/cm³ |

| Melting Point | 466 °C |

| Thermal Expansion | 23 µm/m.°C |

| Modulus of Elasticity | 71.7 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | 33 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 462 Mpa |

| Yield Strength | 560 MPa |

| Shear Strength | 330 MPa |

| Elongation A50 mm | %5 |

| Hardness | 160 HB |

7075 T62 Alclad aluminum alloy is renowned for striking a remarkable balance between high strength, light weight, and corrosion resistance, making it a favored choice in aerospace and defense industries. The T62 heat treatment condition optimizes the already impressive mechanical properties of the 7075 series, while the Alclad coating – a thin layer of pure aluminum – enhances surface corrosion resistance. As a result, this alloy excels in structural components and high-performance applications.

Its suitability for anodizing allows for enhanced surface durability and improved aesthetics. Though the 7075 series is generally considered challenging to weld, specialized techniques and filler materials can enable welding under certain conditions. Similarly, despite its high strength, proper preheating and forming methods can grant a certain degree of bendability, allowing for a limited range of complex shaping.

In environments with intense vibrations and fatigue-inducing loads, 7075 T62 Alclad reliably preserves its strength and structural integrity. This makes it an ideal choice for aircraft wings, fuselage sections, landing gear components, and critical parts of defense vehicles. Additionally, the Alclad surface protection significantly improves corrosion resistance in marine, coastal, or industrial environments, contributing to a longer service life for the finished product.

Among its advantages are its high strength, light weight, excellent corrosion resistance, suitability for anodizing, and the capability to perform well under high-vibration conditions. On the downside, it remains relatively difficult to weld, requires careful machining, and needs special attention during forming to avoid damage. Nevertheless, these characteristics firmly establish 7075 T62 Alclad as a strategic alloy selection where performance, durability, and corrosion resistance are paramount.

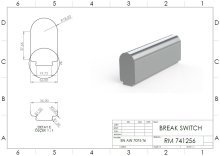

Alclad Sheet and Plate as; 7075 T62, AMS QQ-A-250/13, ASTM B209, EN 2092

Choosing for 7075 T62:

- Strength: High

- Machining: Significant

- Weldability: Low

- Formability: Average

- Corrosion Resistance: Weak

- Heat Treating: Yes

TEMPER TYPES

AMS QQ-A-250/13 7075 is supplied in the following heat treatment types:

- O

- T6

- T62

For special projects in defense industry application.

Firearms production.

- Plate

- Sheet

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| over 0.203 up to & incl. 0.279 | 396 MPa | 465 MPa | 5 |

| over 0.305 up to & incl. 0.991 | 410 MPa | 479 MPa | 7 |

| over 1.02 up to & incl. 1.57 | 423 MPa | 492 MPa | 8 |

| over 1.60 up to & incl. 4.75 | 430 MPa | 498 MPa | 8 |

| over 4.78 up to & incl. 6.32 | 437 MPa | 512 MPa | 8 |

| over 6.35 up to & incl. 12.7 | 444 MPa | 513 MPa | 9 |

| over 12.7 up to & incl. 25.4 | 465 MPa | 533 MPa | 7 |

| over 25.43 up to & incl. 50.8 | 458 MPa | 526 MPa | 6 |

| over 50.8 up to & incl. 63.5 | 438 MPa | 520 MPa | 5 |

| over 63.53 up to & incl. 76.2 | 417 MPa | 491 MPa | 5 |

| over 76.23 up to & incl. 88.9 | 396 MPa | 485 MPa | 5 |

| over 88.93 up to & incl. 102 | 370 MPa | 458 MPa | 4 |

Calculateur de Poids

Calculateur de Poids