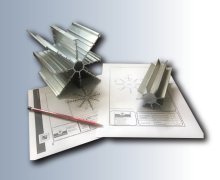

Platos

Hojas

Barras Circulares

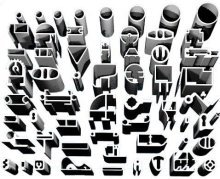

Tubos / Extrusion / Perfil

7075 clad with 7011

AMS QQ-A-250/26 / AlZn5.5MgCu / 7075 clad with 7011 / T76

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,10 - 2,90 |

| Copper (Cu) | 1,20 - 2,00 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 5,10 - 6,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.81 g/cm³ |

| Melting Point | 477°C |

| Thermal Expansion | 23 x 10^-6 /K |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | %33 IACS |

| Mechanical Properties | Value |

| Proof Strength | 503 Mpa |

| Yield Strength | 572 Mpa |

| Shear Strength | 330 MPa |

| Elongation A50 mm | 11% |

| Hardness | 160 HB |

The Alclad aluminum alloy formed by combining 7075 with 7011 introduces a high-strength 7075 core enhanced by a 7011 surface layer, resulting in an ideal blend of corrosion resistance, surface protection, and mechanical robustness. This configuration is frequently chosen for demanding applications in aerospace, defense, automotive, and sports equipment industries. With its exceptional strength-to-weight ratio, structural components remain both lightweight and durable, offering engineers and designers a wide range of possibilities.

This Alclad alloy is suitable for anodizing, which improves surface hardness and aesthetics, ultimately delivering both visually appealing and long-lasting protection. Although alloys in the 7075 series are generally challenging to weld, it is possible under certain conditions when using proper welding techniques and filler materials. Furthermore, despite its inherent hardness, the alloy can be bent to a limited degree if proper preheating and cold forming processes are applied, allowing it to adapt to various manufacturing requirements.

In high-vibration environments, the 7075 core’s strength and fatigue resistance, combined with the 7011 layer’s corrosion-preventive properties, ensure that structural integrity is maintained over the long term. Especially in marine, coastal, or industrial atmospheres, the superior corrosion resistance provided by the 7011 layer extends product lifespan and reduces maintenance costs.

Key advantages include high strength, light weight, improved corrosion resistance, compatibility with anodizing, reliable long-term performance under vibration, and limited but feasible weldability and formability. On the downside, careful machining is required, weldability remains somewhat limited, and additional measures must be taken during forming. Overall, the Alclad combination of 7075 and 7011 offers a strategic material solution that provides an excellent balance of performance, durability, and endurance.

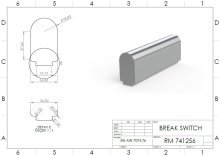

Sheet as; 7075 T76 Alclad 7011 ile, AMS QQ-A-250/26,

ASTM B209, DTD 5110

Choosing Factors for 7075 T76 clad with 7011:

- Strength: Excellent

- Machining: Moderate

- Weldability: Weak

- Formability: Poor

- Corrosion Resistance: Very good

- Heat Treating:Yes

TEMPER TYPES

AMS QQ-A-250/26 7075 is supplied in the following heat treatment types:

- T76

In the production of composite materials and parts in very original projects

Exhaust system design

- Sheet

Sheet as; 7075 T76 Alclad 7011 ile, AMS QQ-A-250/26,

ASTM B209, DTD 5110

Choosing Factors for 7075 T76 clad with 7011:

- Strength: Excellent

- Machining: Moderate

- Weldability: Weak

- Formability: Poor

- Corrosion Resistance: Very good

- Heat Treating:Yes

TEMPER TYPES

AMS QQ-A-250/26 7075 is supplied in the following heat treatment types:

- T76

In the production of composite materials and parts in very original projects

Exhaust system design

- Sheet

Calculador de Peso

Calculador de Peso