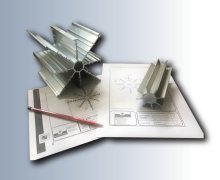

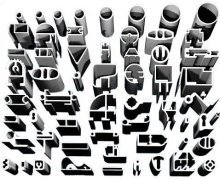

لوحات/ طباقات

صاج

قضيب

أنابيب

7050

AMS 4342 / AlZn6CuMgZr / 7050 / T74511

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,12 |

| Chromium (Cr) | 0,00 - 0,05 |

| Manganese (Mn) | 0,00 - 0,10 |

| Magnesium (Mg) | 2,10 - 2,60 |

| Copper (Cu) | 1,50 - 2,00 |

| Titanium (Ti) | 0,00 - 0,06 |

| Iron (Fe) | 0,00 - 0,15 |

| Zinc (Zn) | 5,70 - 6,70 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,83 g/cm³ |

| Melting Point | 488 °C |

| Thermal Expansion | 23.7 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | 35% IACS |

| Mechanical Properties | Value |

| Proof Strength | 469 MPa |

| Yield Strength | 524 MPa |

| Shear Strength | 303 MPa |

| Elongation A50 mm | 11% |

| Hardness | 140 HB |

A medium strength aerospace aluminium alloy with, depending upon temper, Yield Strength of up to 35 ksi (240 MPa) and Tensile Strength of 42 ksi (290 MPa)

ALLOY DESIGNATIONS

Aluminium alloy QQ-A-250/11, 6061 has s imilarities to the following standard designations and specifications ;

Alloy 6061, UNS A96061, ASTM B209

AMS 4025, AMS 4026, AMS 4027

AIR 9048.210/.220/.230/.240

3.3214

EN 2694, EN 3341, EN 4213

TEMPER TYPES

Alloy QQ-A-250/11 is supplied in a wide range of tempers:

- O - Soft

- T4 - Solution heat treated and naturaly aged to a substantially stable condition

- T42 - Solution heat treated and naturaly aged to a substantially stable condition

- T451 - Solution heat treated then stress relieved by stretching. Equivalent to T4.

- T6 - Solution heat treated and artificially aged

- T62 - Solution heat treated then artificially aged by the user

- T651 - Solution heat treated, stress relieved by stretching then artificially aged

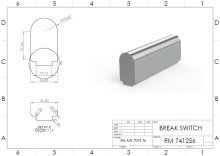

SUPPLIED FORMS

Alloy QQ-A-250/11 is supplied in plate and sheet

- Plate

- Sheet

DELIVERY:

حساب الوزن

حساب الوزن