Dalle

Tôle

Barre ronde

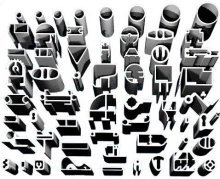

Tube/ Extrusion/ Profil

7050

AMS 4342 / AlZn6CuMgZr / 7050 / T74511

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,12 |

| Chromium (Cr) | 0,00 - 0,05 |

| Manganese (Mn) | 0,00 - 0,10 |

| Magnesium (Mg) | 2,10 - 2,60 |

| Copper (Cu) | 1,50 - 2,00 |

| Titanium (Ti) | 0,00 - 0,06 |

| Iron (Fe) | 0,00 - 0,15 |

| Zinc (Zn) | 5,70 - 6,70 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,83 g/cm³ |

| Melting Point | 488 °C |

| Thermal Expansion | 23.7 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | 35% IACS |

| Mechanical Properties | Value |

| Proof Strength | 469 MPa |

| Yield Strength | 524 MPa |

| Shear Strength | 303 MPa |

| Elongation A50 mm | 11% |

| Hardness | 140 HB |

This alloy is used in aircraft structural parts. The alloy has characteristics of high strength coupled with good resistance to exfoliation and stress corrosion cracking. The alloy also has good fracture toughness and fatigue resistance. Aluminum alloy 7050 is the premier choice for aerospace applications requiring the best combination of strength, stress corrosion cracking (SCC) resistance and toughness.

ALLOY DESIGNATIONS

Aluminium alloy AMS 4050, 7050 has similarities to the following standard designations and specifications ;

Alloy 7050, UNS A97050, ASTM B209

AlZn6CuMgZr, AIR 9048.740

DIN 3.4144, EN3982

TEMPER TYPES

7050 is supplied in a wide range of tempers:

- T73511 - Solution heat-treated, stress-relieved by controlled stretching (permanent set 1% to 3% for extruded rod, bar, shapes and tube, 0.5% to 3% for drawn tube) and then artificially overaged in order to achieve the best stress corrosion resistance. The products receive no further straightening after stretching, except that minor straightening is allowed after stretching to comply with standard tolerances.

- T7451 - Solution heat-treated, stress-relieved by controlled stretching and then artificially overaged (between T73 and T76). The products receive no further straightening after stretching.

- T74511 - Solution heat-treated, stress-relieved by controlled stretching and then artificially overaged (between T73 and T76). The pro-ducts receive no further straightening after stretching, except that minor straightening is allowed after stretching to comply with standard tolerances.

- T76 - Solution heat-treated and then artificially overaged in order to achieve a good exfoliation corrosion resistance.

- T762 - Solution heat-treated and then artificially overaged in order to achieve a good exfoliation corrosion resistan-ce. Applies to test material heat-treated from annealed or F temper or to products heat-treated from any tem-per by the user.

- T7651 - Solution heat-treated, stress-relieved by controlled stretching and then artificially overaged in order to achieve a good exfoliation corrosion resistance. The products recieve no further straightening after stretching.

- T76511 - Solution heat-treated, stress-relieved by controlled stretching and then artificially overaged in order to achieve a good exfoli-ation corrosion resistance. The products receive no further straightening after stretching, except that minor straightening is allowed after stretching to comply with standard tolerances.

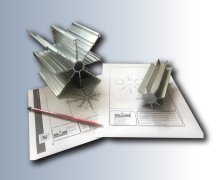

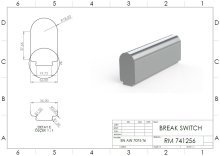

SUPPLIED FORMS

7050 is supplied in plate, sheet, bar and extrusions.

- Plate

- Sheet

- Round Bar / Bar

- Tube / Extrusions

DELIVERY:

Calculateur de Poids

Calculateur de Poids