Platten

Blech

Rundstangen

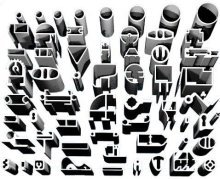

Rohre/ Extrusion/ Profil

7075

QQ-A-200/11 / AlZn5.5MgCu / 7075 / T6510

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,10 - 2,90 |

| Copper (Cu) | 1,20 - 2,00 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 5,10 - 6,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.81 g/cm³ |

| Melting Point | 477°C |

| Thermal Expansion | 23.5 µm/m.°C |

| Modulus of Elasticity | 71.7 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | %33 IACS |

| Mechanical Properties | Value |

| Proof Strength | 510 MPa |

| Yield Strength | 585 MPa |

| Shear Strength | 331 MPa |

| Elongation A50 mm | %10 |

| Hardness | 150 HB |

7075 T6510 is an aluminum alloy Which is preferred in large diameters. in large diameters because the production time is big and the distortion is also big. 7075 T6510 internal tension is removed and vibration resonance is prevented against where the material will be used. Highly preferred to avoid risk in high-cost projects.

ALLOY DESIGNATIONS

7075 T6510 has similarities to the following standard designations and specifications ;

Cold Drawn Rod, Flat Bar as; 7075 T6510, AMS QQ-A-225/9,

ASTM B211

Extrusion Rod, Flat Bar as; 7075 T6510, AMS QQ-A-200/11,

ASTM B221

Choosing Factors for 7075 T6510:

- Strength: High

- Machining: Good

- Weldability: Poor

- Formability: Average

- Corrosion Resistance: Low

- Heat Treating:Yes

TEMPER TYPES

AMS QQ-A-200/11 7075 is supplied in the following heat treatment types:

- O

- T6

- T6510

- T6511

- T73

- T735111

Some Well-Known Applications for 7075 T6510:

In parts subjected to high acceleration momentum force,

In projects Where the Vibration-Stabilization is very important.

Firearms and ammunition production

In the production of all kinds of parts and connection equipment with thin-walled and sensitive tolerance ..

SUPPLIED FORMS

7075 T6510 is supplied in rod,round bar and flat bar form.

- Rod / Round Bar / Flat Bar

DELIVERY:

Gewichts-Kalkulator

Gewichts-Kalkulator