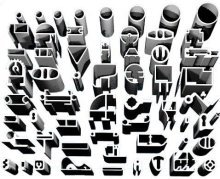

冷拔 铝圆棒

冷拔 圆管

7075

Cold Drawn/Finished (CF) / AlZn5.5MgCu (Soğuk Çekim) / 7075 / T6

| 化学性质 | % 值 |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,10 - 2,90 |

| Copper (Cu) | 1,20 - 2,00 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 5,10 - 6,10 |

| Aluminium (Al) | Balance |

| 物理特性 | 值 |

| Density | 2.81 g/cm³ |

| Melting Point | 466 °C |

| Thermal Expansion | 23.4 µm/m.°C |

| Modulus of Elasticity | 71.7 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | %33 IACS |

| 机械性能 | 值 |

| Proof Strength | 480 MPa |

| Yield Strength | 560 MPa |

| Shear Strength | 330 MPa |

| Elongation A50 mm | %8 |

| Hardness | 150 HB |

Sheet as; AMS QQ-A-250/12, AMS 4045,ASTM B209, EN 2696

Alclad Sheet as; AMS QQ-A-250/13,AMS 4049,ASTM B209, AIR 9048-280, BS 2 L88, WL 3.4374, DAN 424,EN 2092

Oneside Alclad Sheet as; AMS QQ-A-250/18, AMS 4154, ASTM B209

Extrusion Seamless Pipe as; AMS QQ-A-200/11, AMS 4154, ASTM B241

Extrusion Rod, Flat Bar, Wire as; AMS QQ-A-200/11, AMS 4154, ASTM B221

Cold Drawn Rod,Flat Bar,Wire as; AMS QQ-A-255/9,AMS 4122,ASTM B211

Cold Drawn Seamless Pipe as; AMS-T-700/7, ASTM B210

Alloy 7075, UNS A97075, AlZn5.5MgCu, DIN 3.4365, A-Z5GU

Choosing Factors for 7075 T6

- Strength: Excellent

- Machining: Good

- Weldability: Poor

- Formability: Modarate

- Corrosion Resistance: Low

- Heat Treating: Yes

Some Well-Known Applications for 7075 T6:

It is used in manyplaces from supersonic aircraft to sewing machine apparatus .

Shoe injection mold, nuclear reactors.

Hundreds of industries as coil, spring, flange

- Sheet

- Rod / Round Bar / Flat Bar

| 机械性能 | |||

| 厚度 (mm) | 证明力量 (Min.) | 屈服强度 (Min.) | Uzama % |

| over 0.203 up to & incl. 0.279 | 430 MPa | 505 MPa | 5 |

| over 0.305 up to & incl. 0.991 | 458 MPa | 520 MPa | 7 |

| over 1.02 up to & incl. 3.17 | 465 MPa | 535 MPa | 8 |

| over 3.20 up to & incl. 6.32 | 472 MPa | 533 MPa | 8 |

| over 6.35 up to & incl. 12.7 | 459MPa | 534 MPa | 9 |

| over 12.7 up to & incl. 25.4 | 465 MPa | 538 MPa | 7 |

| over 25.43 up to & incl. 50.8 | 457 MPa | 526 MPa | 6 |

| over 50.83 up to & incl. 63.5 | 437 MPa | 519 MPa | 5 |

| over 63.53 up to & incl. 76.2 | 417 MPa | 491 MPa | 5 |

| over 76.23 up to & incl. 88.9 | 394 MPa | 485 MPa | 5 |

| over 88.93 up to & incl. 102 | 368 MPa | 458 MPa | 4 |

计算 重量计算

计算 重量计算