Platos

Hojas

Barras Circulares

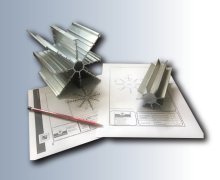

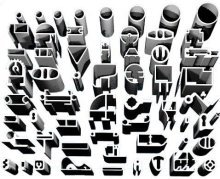

Tubos / Extrusion / Perfil

1200

ASTM B210 / Al99.0 / 1200 / O

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,10 |

| Manganese (Mn) | 0,00 - 0,05 |

| Copper (Cu) | 0,00 - 0,05 |

| Titanium (Ti) | 0,00 - 0,05 |

| Iron (Fe) | 0,00 - 1,00 |

| Zinc (Zn) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,70 g/cm³ |

| Melting Point | 654°C |

| Thermal Expansion | 23.4 µm/m.°C |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 230 W/m.K |

| Electrical Resistivity | %59 IACS |

| Mechanical Properties | Value |

| Proof Strength | 29 MPa |

| Yield Strength | 88 MPa |

| Shear Strength | 57 MPa |

| Elongation A50 mm | 28% |

| Hardness | 23 HB |

The 1200 O aluminum alloy is known for its excellent machinability, outstanding corrosion resistance, and low mechanical strength. The O temper represents the softest form of the alloy, making the 1200 O aluminum alloy highly malleable and easy to process. Due to these characteristics, 1200 O aluminum is commonly used in applications such as electrical devices, packaging materials, heat exchangers, weather-resistant structures, and general engineering applications. Additionally, 1200 O alloy is suitable for anodizing, which enhances its surface appearance and increases its corrosion resistance.

In terms of weldability, 1200 O aluminum alloy can be easily welded. Its soft structure and low hardness make welding straightforward, although it may not be suitable for applications requiring high strength and durability. When it comes to bending, 1200 O aluminum is highly flexible and easily shaped. Its soft nature allows for easy bending and forming, making it suitable for a wide range of applications.

The corrosion resistance of 1200 O aluminum alloy is excellent. It performs well against atmospheric conditions and harsh environments, such as seawater, making it ideal for outdoor and maritime applications. However, the use of 1200 O aluminum in high-vibration environments may be limited, as its lower mechanical strength could lead to performance degradation under such conditions.

The advantages of 1200 O aluminum alloy include excellent machinability, high corrosion resistance, and anodizing compatibility. However, its low mechanical strength makes it unsuitable for applications that require high load-bearing capacity or durability. Additionally, its performance in high-vibration environments may be limited. Despite these drawbacks, the low cost and high machinability make 1200 O aluminum alloy an excellent choice for lightweight applications and aesthetic purposes.

Choosing Factors for 1200 O

- Strength: Average

- Machining: Poor

- Weldability: Excellent

- Formability: Very good

- Corrosion Resistance: Perfect

- Heat Treating: Yes

Some Well-Known Applications for 1200 O

In home furniture and lighting parts,

In bottle production,

Also used in kitchenware.

- Sheets

- Round/Flat Bar

- Tube/Profile

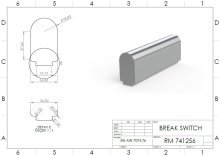

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Min %20 | |||

Calculador de Peso

Calculador de Peso