Platos

Hojas

Barras Circulares

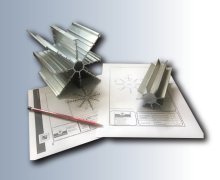

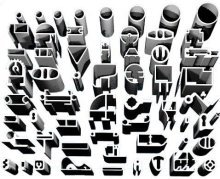

Tubos / Extrusion / Perfil

2014A

ASTM B928 / AlCu4SiMg / 2014A / T3510/ T3511

| Chemical Properties | % Value |

| Silicon (Si) | 0,50 - 1,20 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,40 - 1,20 |

| Magnesium (Mg) | 0,20 - 0,80 |

| Copper (Cu) | 3,90 - 5,00 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.80 g/cm³ |

| Melting Point | 507 °C |

| Thermal Expansion | 22.7 µm/m.°C |

| Modulus of Elasticity | 73 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | %34 IACS |

| Mechanical Properties | Value |

| Proof Strength | 320 MPa |

| Yield Strength | 430 MPa |

| Shear Strength | 250 MPa |

| Elongation A50 mm | 7% |

| Hardness | 100 HB |

2014A T3510/T3511 aluminum exhibits high strength and is widely used in aerospace applications.

ALLOY DESIGNATIONS

2014A T3510/T3511 has the following standard designations and specifications.

As Cold Drawn Tube: 2014A T3510/ T3511, ASTM B211, UNS A92014, ASTM B928, WNR 3.1255, ISO AlCu4SiMg

Choosing Factors for 2014A T3510/T3511

- Strength: Very good

- Machining: Great

- Weldability: Bad

- Formability: Okay

- Corrosion Resistance: Weak

- Heat Treating: Yes

Some Well-Known Applications for 2014A T3510/T3511

Mainly in the aerospace sector and defense industry,

In the production of military vehicles and weapons,

It is also used in pipelines and the automotive industry.

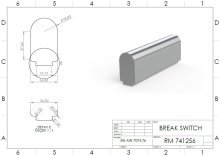

SUPPLIED FORMS

2014A T3510/ T3511 is produced/supplied in tube/profile forms.

- Tube/Profile

DELIVERY:

Calculador de Peso

Calculador de Peso