Platten

Blech

Rundstangen

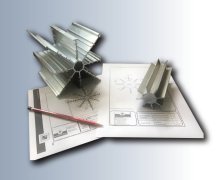

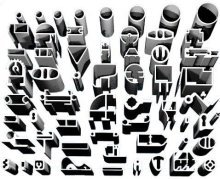

Rohre/ Extrusion/ Profil

2014

AMS 4028 / AlCu4SiMg / 2014 / O

| Chemical Properties | % Value |

| Silicon (Si) | 0,50 - 1,20 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,40 - 1,20 |

| Magnesium (Mg) | 0,20 - 0,80 |

| Copper (Cu) | 3,90 - 5,00 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.80 g/cm³ |

| Melting Point | 507 °C |

| Thermal Expansion | 22.7 µm/m°C |

| Modulus of Elasticity | 73 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | 40 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 100 MPa |

| Yield Strength | 190 MPa |

| Shear Strength | 130 MPa |

| Elongation A50 mm | %17 |

| Hardness | 48 HB |

The 2014 O aluminum alloy is known for its high strength and good machinability. As part of the aluminum-copper alloy family, it is commonly used in structural applications, the automotive industry, and aerospace, where high performance is required. The O temper, achieved through specific heat treatments, provides the alloy with low hardness and flexibility, enhancing machinability and formability. These characteristics make the 2014 O aluminum alloy ideal for applications that require high durability and flexibility.

The 2014 O aluminum alloy is generally not suitable for anodizing. Its high copper content prevents the formation of an effective oxide layer during anodizing, making it difficult to protect the alloy through this process. Instead, other coating methods are typically used for protection. In terms of weldability, the 2014 O aluminum alloy performs well when proper welding techniques are used. However, due to its copper content, careful handling is required during welding to prevent cracking, and correct welding procedures must be followed.

In terms of bending and forming, the 2014 O aluminum alloy is easy to shape due to its low hardness. This makes it ideal for producing complex shapes in industries such as automotive, aerospace, and construction. However, its use in high-vibration environments is limited, as the copper content makes the material more brittle. It is more suitable for low-load and low-vibration applications.

Regarding corrosion resistance, the 2014 O aluminum alloy has limited resistance compared to other aluminum alloys due to its high copper content. However, this limitation can be overcome with appropriate coatings and surface treatments. The advantages of the 2014 O alloy include high strength, good machinability, and flexibility, while its disadvantages include limited corrosion resistance and challenges in welding.

As Sheet/Plate; 2014 O, ISO AlCu4SiMg, MIL-A-21180, ASTM B209, UNS A92014, WNR 3.1255, AMS 4028 (Superseded the AMS 4014)

As Extruded Round/Flat Bar; 2014 O, ASTM B221, UNS A92014,, WNR 3.1255

As Cold Drawn Round/Flat Bar: 2014 O, ASTM B211, UNS A92014, ASTM B928, WNR 3.1255

Choosing Factors for 2014 O

- Strength: Great

- Machining: Very good

- Weldability: Poor

- Formability: Good

- Corrosion Resistance: Weak

- Heat Treating: Yes

Some Well-Known Applications for 2014 O

In the aerospace sector,

In pipelines and as truck and machinery equipment,

It is also used in power plants and in the automotive industry in general.

- Plate/ Sheet

- Rod / Round Bar / Flat Bar

- Tube/Profile

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 4.57 up to & incl. 12.7 mm | 100 MPa | 185 MPa | 15% |

| Over 12.7 up to & incl. 25.4 mm | 110 MPa | 200 MPa | 17% |

Gewichts-Kalkulator

Gewichts-Kalkulator