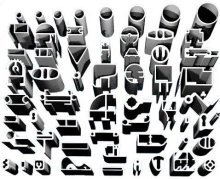

Калиброванные прутки

Трубы волоченые

7075

Cold Drawn/Finished (CF) / AlZn5.5MgCu (Soğuk Çekim) / 7075 / T73510

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,10 - 2,90 |

| Copper (Cu) | 1,20 - 2,00 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 5,10 - 6,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.81 g/cm³ |

| Melting Point | 477°C |

| Thermal Expansion | 23 µm/m.°C |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 155 W/m.K |

| Electrical Resistivity | 33% IACS |

| Mechanical Properties | Value |

| Proof Strength | 420 MPa |

| Yield Strength | 515 MPa |

| Shear Strength | 292 MPa |

| Elongation A50 mm | %8 |

| Hardness | 135 HB |

7075 T73510 rod is mostly preferred as cold drawn. Compared to T6510, 7075 T73510 aluminum is preferred in small diameters. When T73510 is used as 7075 aluminum which is made stronger the corrosion resistance and inner stress removal, it provides high performance in small diameters.

ALLOY DESIGNATIONS

7075 T73510 has similarities to the following standard designations and specifications ;

Cold Drawn Rod, Flat Bar, Profile as; 7075 T73510, AMS QQ-A-225/9,

ASTM B211

Choosing Factors for 7075 T73510:

- Strength: Significant

- Machining: Average

- Weldability: Low

- Formability: Poor

- Corrosion Resistance: Fair

- Heat Treating:Yes

TEMPER TYPES

AMS QQ-A-225/9 7075 is supplied in the following heat treatment types:

- O

- T6

- T651

- T73510

Some Well-Known Applications for 7075 T73510:

In the manufacture of rifles,

Bicycle industry

Production of gears operating at high temperatures and frequencies

SUPPLIED FORMS

7075 T73510 is supplied in rod / round bar / flat bar form.

- Rod / Round Bar / Flat Bar

DELIVERY:

Калькулятор Веса

Калькулятор Веса