板/板

钣金

棒条/金属板

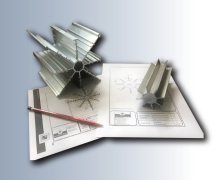

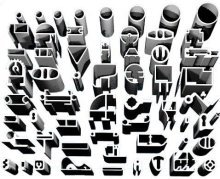

管道/型材

6005A

ASTM B221 / AlSiMg(A) / 6005A / T6

| 化学性质 | % 值 |

| Silicon (Si) | 0,50 - 0,90 |

| Chromium (Cr) | 0,00 - 0,30 |

| Manganese (Mn) | 0,00 - 0,50 |

| Magnesium (Mg) | 0,40 - 0,70 |

| Copper (Cu) | 0,00 - 0,30 |

| Titanium (Ti) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,35 |

| Zinc (Zn) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| 物理特性 | 值 |

| Density | 2.63 g/cm³ |

| Melting Point | 582 °C |

| Thermal Expansion | 23.4 µm/m.°C |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 189 W/m.K |

| Electrical Resistivity | %49 IACS |

| 机械性能 | 值 |

| Proof Strength | 230 MPa |

| Yield Strength | 280 MPa |

| Shear Strength | 170 MPa |

| Elongation A50 mm | 9% |

| Hardness | 95 HB |

The 6005A T6 aluminum alloy is known for its high mechanical strength, excellent corrosion resistance, and good formability. This alloy is widely used in industries such as automotive, construction, transportation, and industrial structures. As a heat-treated alloy, 6005A T6 offers high tensile strength, making it ideal for heavy-load-bearing applications. Additionally, it is suitable for anodizing, which enhances its surface appearance and provides extra corrosion resistance.

This alloy also offers excellent weldability, making it highly advantageous in industrial production processes. When the proper welding techniques are applied, 6005A T6 can be easily welded, making it suitable for a wide range of applications. Moreover, it has good bending properties, providing high machinability that facilitates easy shaping and the ability to achieve desired forms without difficulty.

The corrosion resistance of 6005A T6 aluminum alloy is quite high. It performs well in harsh environments, such as marine applications, but may experience some weakening in extremely abrasive environments. It is also suitable for use in high-vibration environments, making it ideal for dynamic industries like automotive, aerospace, and defense, where vibration resistance is essential. The high durability and long lifespan make 6005A T6 a preferred choice in many applications.

The advantages of 6005A T6 include its high mechanical strength, corrosion resistance, anodizing compatibility, weldability, and bending properties. However, it does have some drawbacks, such as reduced hardness at low temperatures and limited performance in highly abrasive environments. Despite these limitations, 6005A T6 is an excellent choice for applications that require high performance and durability.

Choosing Factors for 6005A T6

- Strength: Moderate

- Machining: Fair

- Weldability: Very good (Arc welding is the best choice)

- Formability: Moderate

- Corrosion Resistance: Good

- Heat Treating: Yes

Some Well-Known Applications for 6005A T6

In tubings of furnitures,

In railway transport industry and buses,

It is also used in ladder construction.

- Rod / Round Bar / Flat Bar

- Tube/Profile

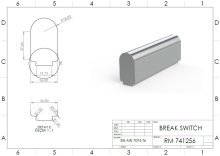

| 机械性能 | |||

| 厚度 (mm) | 证明力量 (Min.) | 屈服强度 (Min.) | Uzama % |

| Over 0.2 up to & incl. 0.5 | 241 | 290 | %8 |

| Over 0.5 up to & incl. 6.5 | 241 | 290 | %10 |

计算 重量计算

计算 重量计算