Platten

Blech

Rundstangen

Rohre/ Extrusion/ Profil

2024

AMS QQ-A-250/4 / AlCu4Mg1 / 2024 / T3

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,50 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,30 - 0,90 |

| Magnesium (Mg) | 1,2 - 1,80 |

| Copper (Cu) | 3,80 - 4,90 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.78 g/cm³ |

| Melting Point | 502 °C |

| Thermal Expansion | 23 µm/m.°C |

| Modulus of Elasticity | 73.1 GPa |

| Thermal Conductivity | 121 W/m.K |

| Electrical Resistivity | 30% IACS |

| Mechanical Properties | Value |

| Proof Strength | 320 MPa |

| Yield Strength | 480 MPa |

| Shear Strength | 283 MPa |

| Elongation A50 mm | 10% - 16% |

| Hardness | 120 HB |

The 2024 T3 aluminum alloy is renowned for its high strength and fatigue resistance. As part of the aluminum-copper alloy group, this material undergoes solution heat treatment followed by natural aging, providing both strength and machinability. Known for its lightweight and durability, 2024 T3 is widely used in the aerospace industry, particularly in critical structural components such as aircraft fuselages, wings, and landing gear.

This alloy has limited suitability for anodizing. Its high copper content prevents the formation of an effective oxide layer during anodizing, so alternative coating methods are typically used to protect the surface. In terms of weldability, 2024 T3 requires careful handling. The copper content increases the risk of cracking during welding, so specialized welding techniques and appropriate filler materials are recommended to ensure reliable joints.

The 2024 T3 aluminum alloy offers good formability, making it suitable for producing complex shapes. Due to its high strength, bending and forming processes require careful attention. This alloy is well-suited for high-vibration environments because its excellent fatigue resistance and elastic modulus make it highly resistant to vibrations and continuous loading. Its lightweight, fatigue resistance, and strength also make it a preferred choice in the automotive and defense industries.

However, its corrosion resistance is relatively limited compared to other aluminum alloys, as the copper content reduces its ability to resist corrosion. This limitation can be addressed with proper surface treatments and coatings. The advantages of 2024 T3 include high strength, lightweight properties, and fatigue resistance, while its disadvantages include limited corrosion resistance and challenges in welding. These characteristics make 2024 T3 an ideal choice for projects that demand high performance and durability.

ALLOY DESIGNATIONS

Aluminium alloy 2024 T3 has similarities to the following standard designations and specifications:

As round bar: 2024 T3, AMS QQ-A-200/3, AMS 4152, ASTM B221

As plate and sheet: 2024 T3, AMS QQ-A-250/4, AMS 4037, AIR 9048-110, WS 3.1354, ASTM B209

As tube: 2024 T3, WW-T-700/3, AMS 4086, ASTM B211

As alclad sheet: 2024 T3, AMS QQ-A-250/5, AMS 4041, AIR 9048-140, ASTM B209, BSL 109, WS 3.1364, EN 2090

Choosing Factors for 2024 T3

- Strength: Good

- Machining: Okay

- Weldability: Mid (Spot welding is the best choice)

- Formability: Weak

- Corrosion Resistance: Weak

- Heat Treating: Yes

Some Well-Known Applications for 2024 T3

Seat beams in aircrafts,

Torque tubes in aircraft tails,

It is also used in seat baggage bars.

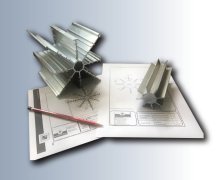

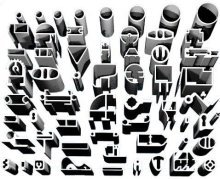

SUPPLIED FORMS

2024 T3 is supplied in plate, sheet, bar and extrusions.

- Plate

- Sheet

- Round Bar / Bar

- Tube / Extrusions

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| over 0,2 up to & incl. 0,25 mm | 290 | 435 | 10% - 15% |

| over 0,25 up to & incl. 0,35 mm | 305 | 441 | 10% - 15% |

| over 0,35 up to & incl. 0,65 mm | 311 | 443 | 10% - 15% |

| over 3,28 up to & incl. 6,32 mm | 330 | 450 | ≥15% |

| over 6,35 up to & incl. 12,7 mm | 290 | 440 | ≥15% |

Gewichts-Kalkulator

Gewichts-Kalkulator