Cold Drawn Round Bar

Cold Drawn Tube

2017A

Cold Drawn/Finished (CF) / AlCu4MgSi(A) (Soğuk Çekim) / 2017A / T42

| Chemical Properties | % Value |

| Silicon (Si) | 0,20 - 0,80 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,40 - 1,0 |

| Magnesium (Mg) | 0,40 - 1,00 |

| Copper (Cu) | 3,50 - 4,50 |

| Titanium (Ti) | 0,00 - 0,25 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.79 g/cm³ |

| Melting Point | 510 °C |

| Thermal Expansion | 22.9 µm/m.°C |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | 34 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 260 MPa |

| Yield Strength | 440 MPa |

| Shear Strength | 270 MPa |

| Elongation A50 mm | 14% |

| Hardness | 110 HB |

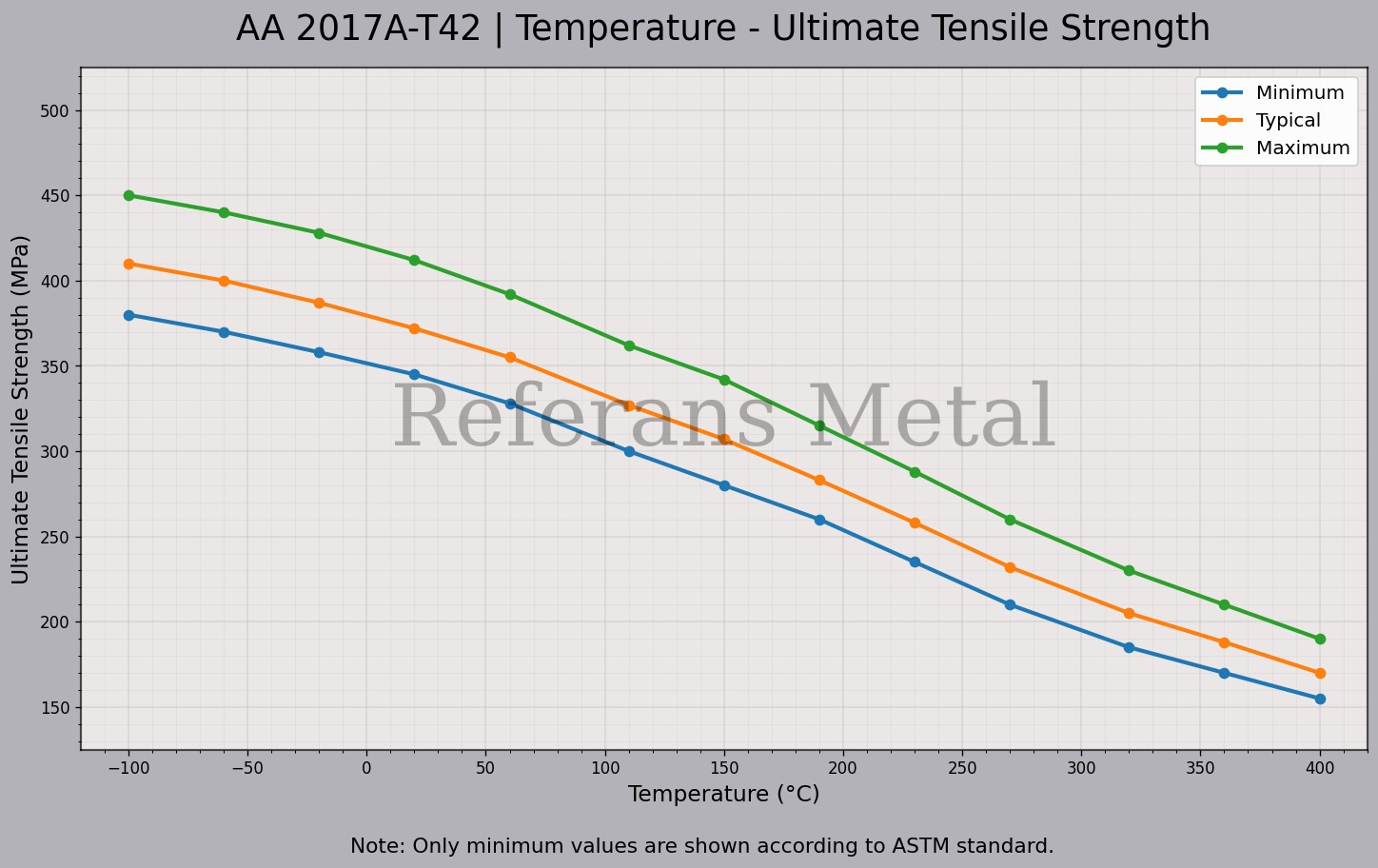

| 2017A T42 Temperature – Ultimate Tensile Strength Graph |

|

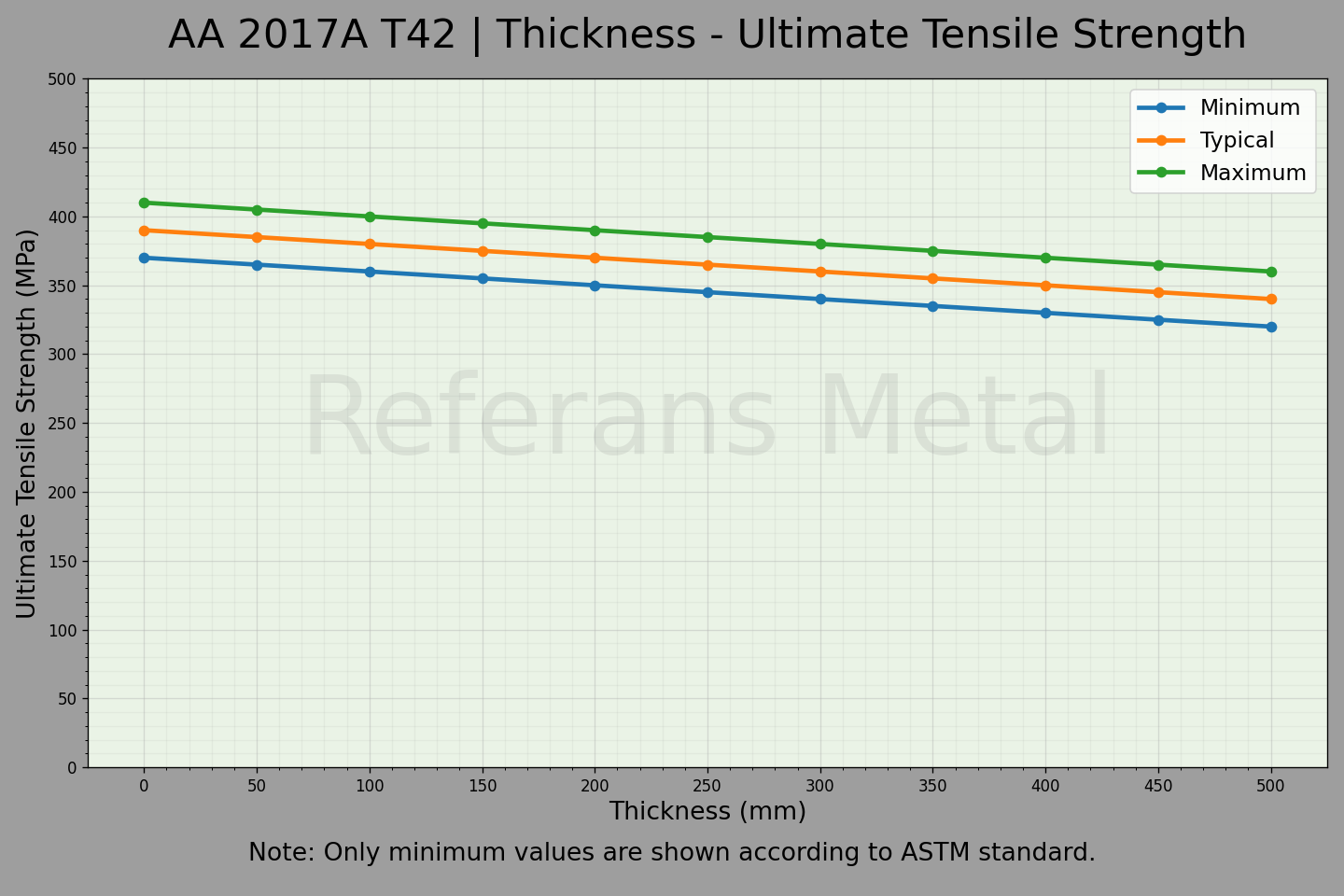

| 2017A T42 Thickness – Ultimate Tensile Strength Graph |

|

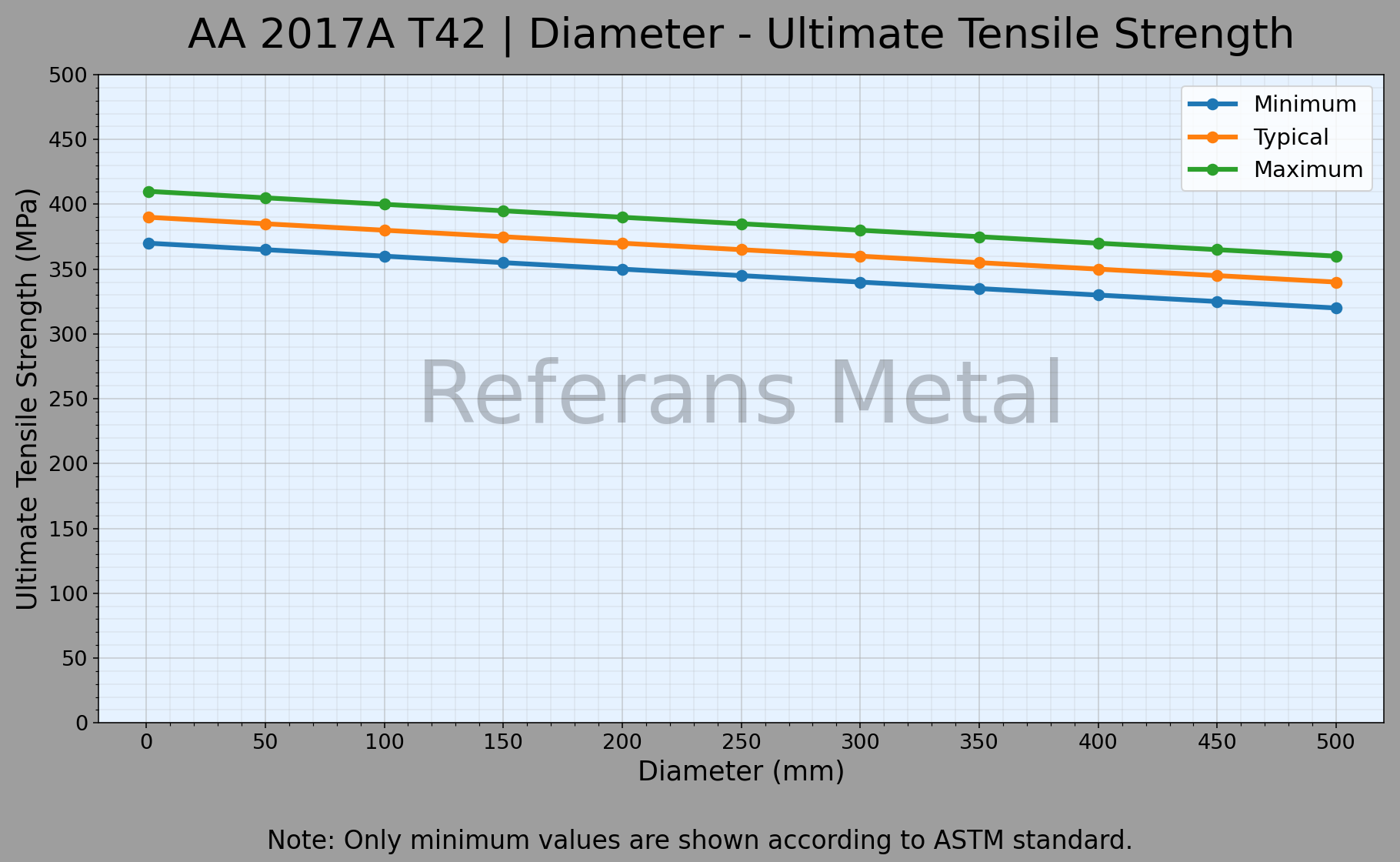

| 2017A T42 Diameter – Ultimate Tensile Strength Graph |

|

The 2017A T42 aluminum alloy is a high-strength alloy of the 2000 series, notable for its high copper (Cu) content. Its typical composition is approximately 3.5–4.5% Cu, 0.4–1.0% Mg, 0.4–1.0% Mn, and 0.2–0.8% Si. The T42 temper involves solution heat treatment followed by a stress-relief process, which stabilizes natural aging. This process allows the alloy to maintain high strength while providing dimensional stability and precise tolerances. These characteristics make 2017A T42 particularly ideal for structural applications and load-bearing components.

In terms of strength, 2017A T42 is quite robust. Tensile strength typically ranges from 400–480 MPa, while yield strength is between 250–350 MPa. Elongation is around 10–12%, indicating that the alloy is not overly brittle and has adequate ductility. This combination provides advantages in durability and load distribution for structural parts under high stress. Additionally, the fatigue resistance of 2017A T42 is very good, ensuring reliable performance under vibrational or cyclic loading conditions.

Regarding machinability, 2017A T42 is suitable for CNC milling, drilling, turning, pressing, and extrusion, generally offering high workability. The T42 temper helps maintain dimensional stability and predictable behavior during production. However, due to its copper content, the alloy’s corrosion resistance is limited. In humid, marine, or aggressive chemical environments, additional surface protection such as anodizing, coating, or painting may be required.

In terms of applications, 2017A T42 is widely used in the aerospace and aviation industry, automotive sector, mechanical engineering, and general industrial applications. Its high strength, light weight, machinability, and adequate ductility make it ideal for critical components such as wing spars, structural supports, fasteners, vehicle bodies, and machine parts. Furthermore, the alloy offers a flexible and reliable option for manufacturers seeking both durability and dependability.

MATERIAL COMPOSITION STANDARDS

2017A T42 can conform to the following standards:

• 2017A T42 Plate; ASTM B209, ISO AlCu4MgSi, UNS A92017, WNR 3.1325, DIN AlCuMg1, EN 485-2

• 2017A T42 Sheet; ASTM B209, ISO AlCu4MgSi, UNS A92017, WNR 3.1325, DIN AlCuMg1, EN 485-2

• 2017A T42 Cold Drawn Round Bar; AMS QQ-A-225/5, ASTM B211, UNS A92017, ASTM B565, ASTM B316, WNR 3.1325, DIN AlCuMg1, BS EN 2116:2009

• 2017A T42 Cold Drawn Bar; AMS QQ-A-225/5, ASTM B211, UNS A92017, ASTM B565, ASTM B316, WNR 3.1325, DIN AlCuMg1, BS EN 2116:2009

• 2017A T42 Cold Drawn Wire; AMS QQ-A-225/5, ASTM B211, UNS A92017, ASTM B565, ASTM B316, WNR 3.1325, DIN AlCuMg1, BS EN 2116:2009

Characteristic Properties of 2017A T42:

- Strength: High

- Machinability: Very Good

- Weldability: Medium (Filler welding and brazing are preferred)

- Formability: Very Good

- Corrosion Resistance: Moderate (Improved with coating)

- Heat Treatable: Yes

Common Applications of 2017A T42:

Used as structural material in construction and transportation industries,

In the aerospace and aviation sector,

In rivets and high-strength structures.

STOCK

We supply 2017A T42 in plate/sheet, sheet, rod/bar, and pipe/profile forms.

- Plate / Sheet

- Sheet

- Rod / Bar

- Pipe / Profile

BS EN 2116:2009

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 25 up to & incl. 75 | 270 MPa | 400 MPa | %10 |

| Over 75 up to & incl. 150 | 260 MPa | 390 MPa | %9 |

| Over 150 up to & incl. 200 | 240 MPa | 370 MPa | %8 |

| Over 200 up to & incl. 250 | 220 MPa | 360 MPa | %7 |

Weight Calculator

Weight Calculator