Cold Drawn Round Bar

Cold Drawn Tube

2014A

Cold Drawn/Finished (CF) / AlCu4SiMg (Soğuk Çekim) / 2014A / T651

| Chemical Properties | % Value |

| Silicon (Si) | 0,50 - 0,90 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,40 - 1,20 |

| Magnesium (Mg) | 0,20 - 0,80 |

| Copper (Cu) | 3,90 - 5,00 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,25 |

| Nickel (Ni) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.80 g/cm³ |

| Melting Point | 507 °C |

| Thermal Expansion | 22.5 µm/m.°C |

| Modulus of Elasticity | 73 GPa |

| Thermal Conductivity | 155 W/m.K |

| Electrical Resistivity | 37% IACS |

| Mechanical Properties | Value |

| Proof Strength | 414 MPa |

| Yield Strength | 510 MPa |

| Shear Strength | 290 MPa |

| Elongation A50 mm | 7% |

| Hardness | 135 HB |

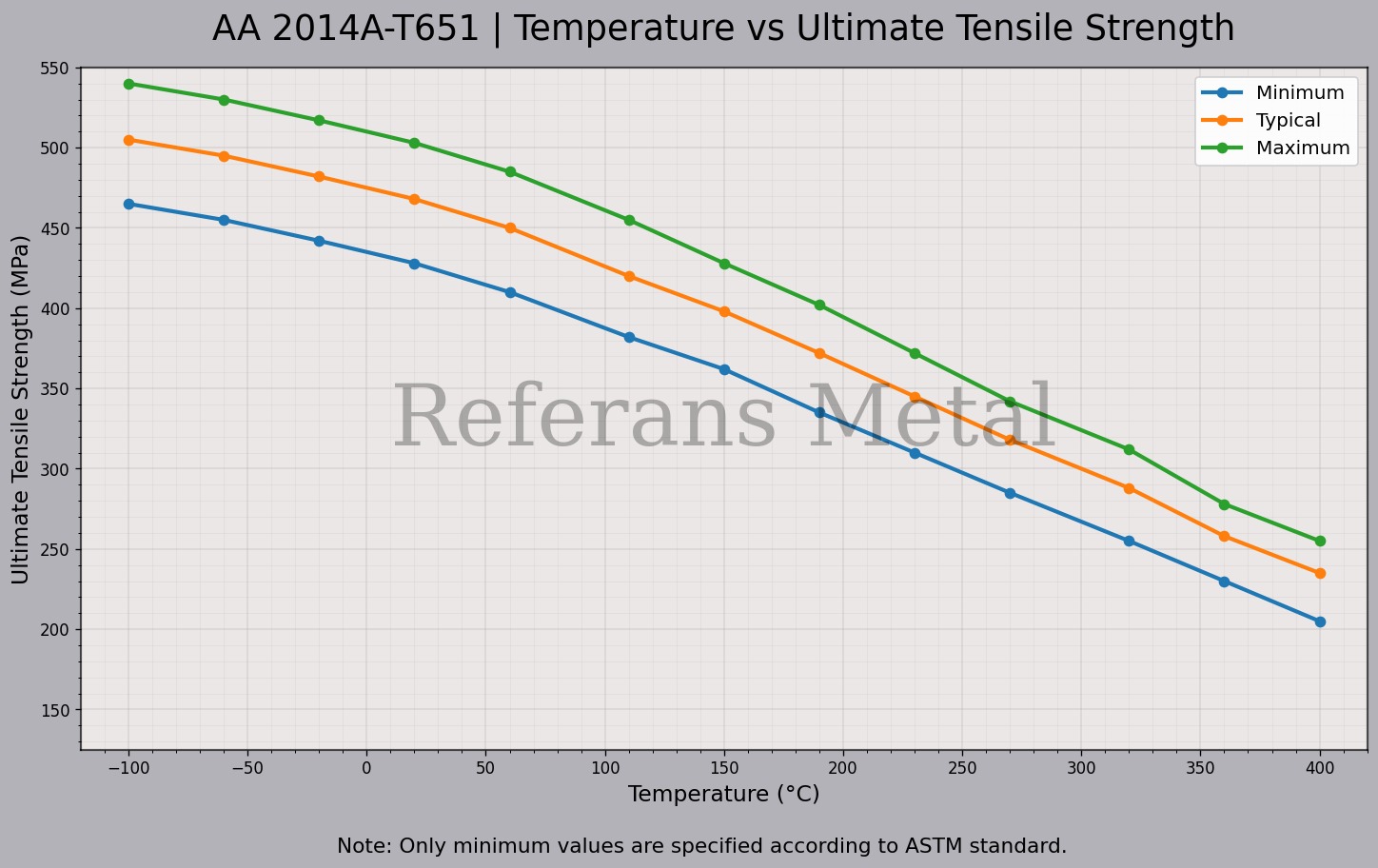

| 2014A T651 Temperature – Ultimate Tensile Strength Graph |

|

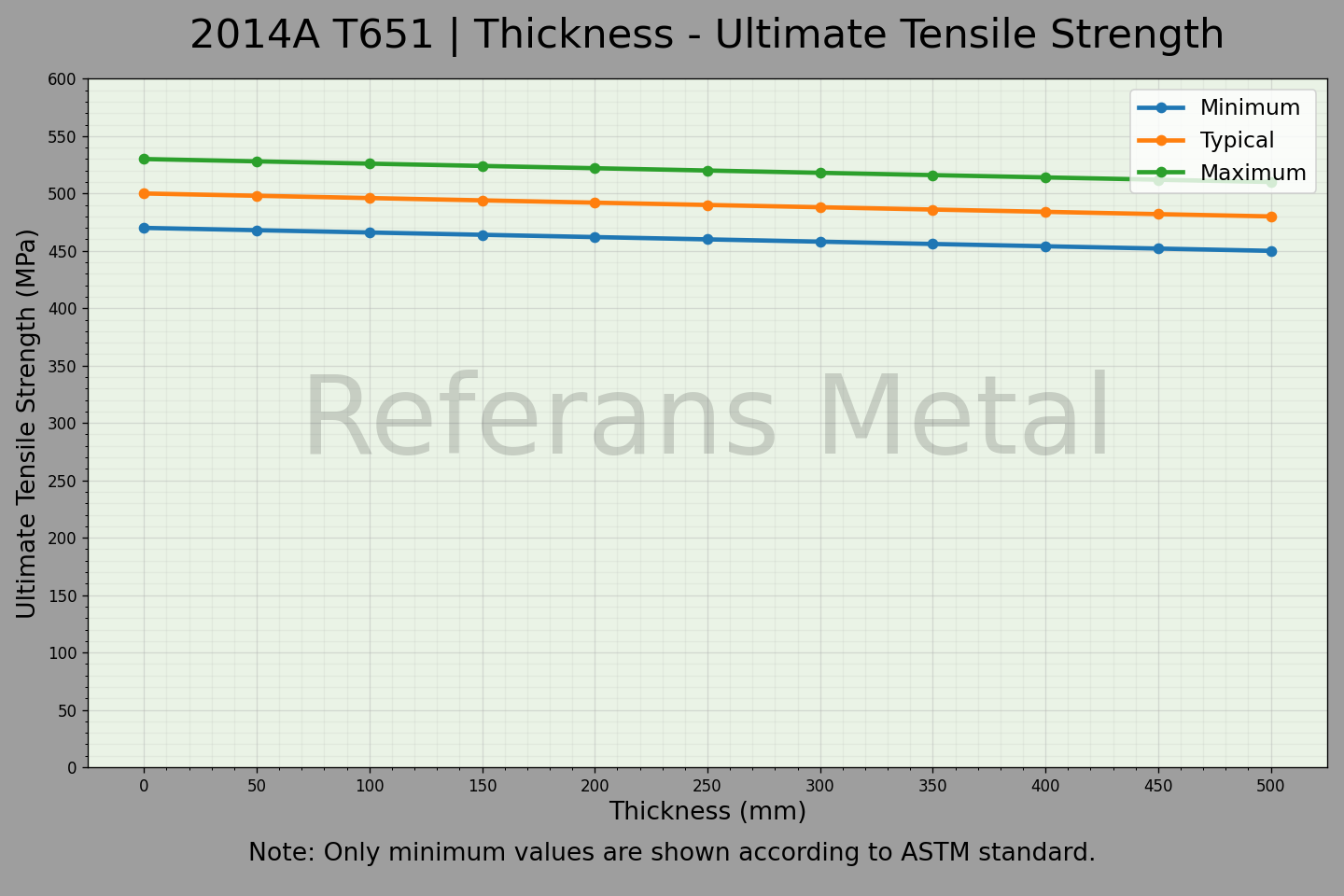

| 2014A T651 Thickness – Ultimate Tensile Strength Graph |

|

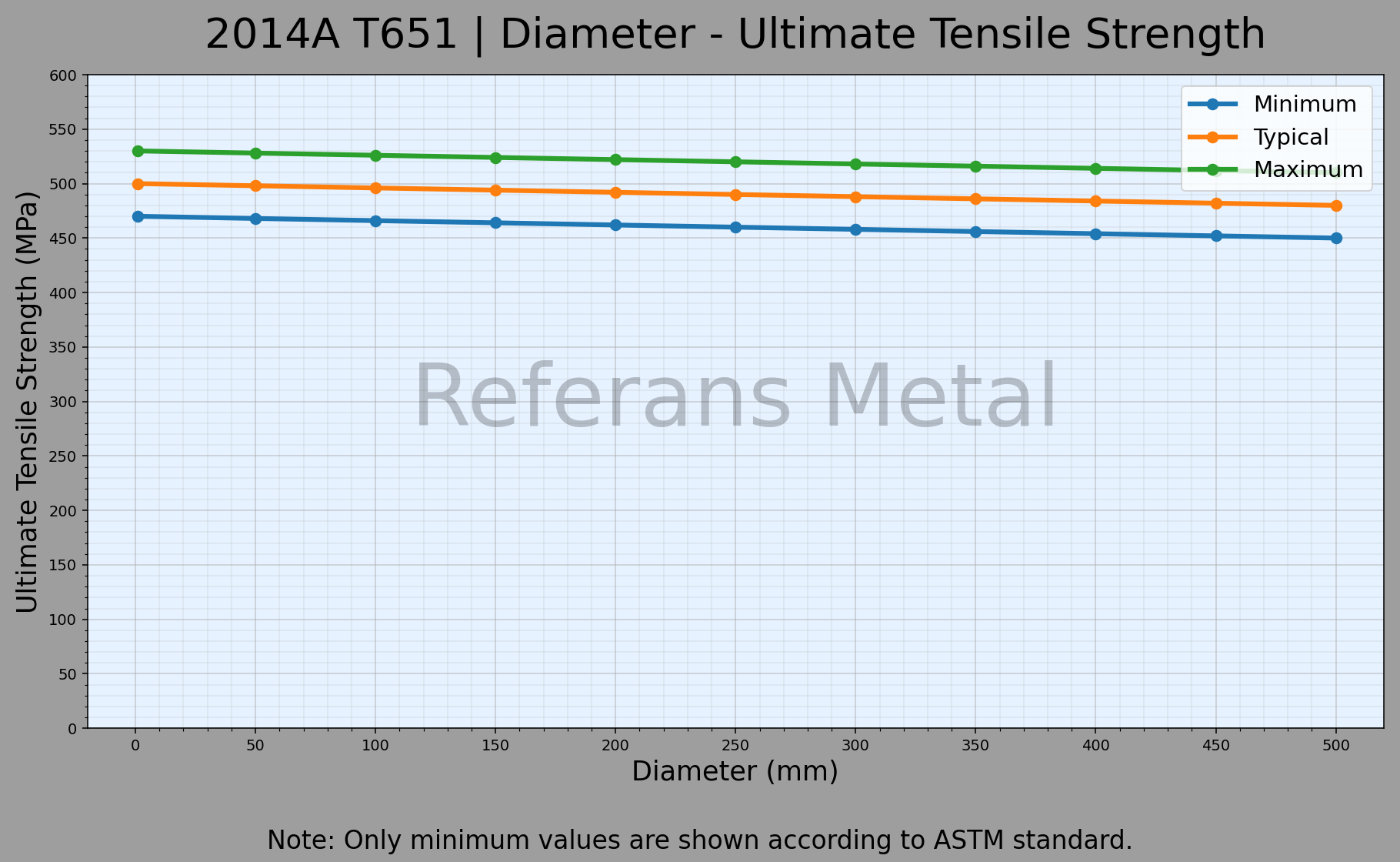

| 2014A T651 Diameter – Ultimate Tensile Strength Graph |

|

2014A T651 is a high-strength aluminum alloy belonging to the 2000 series and is strengthened with copper (Cu) additions. The “T651” temper indicates that the alloy has undergone solution heat treatment, followed by stress-relief heat treatment to eliminate residual stresses, and is then stabilized by natural aging. This process reduces internal stresses while providing high strength, offering significant advantages in engineering applications where dimensional stability and tight tolerances are critical. The chemical composition of the alloy typically includes approximately 3.9–4.5% Cu, 0.4–1.0% Mn, 0.4–0.8% Mg, and 0.2–0.8% Si, which enhances mechanical performance through heat treatment hardening.

In terms of strength, 2014A T651 is quite high; typical tensile strength ranges between 440–470 MPa, while yield strength is in the range of 270–300 MPa. Elongation is approximately 10–12%. These properties make the alloy suitable for structural components exposed to high loads in aerospace, defense industry, heavy machinery, and automotive sectors. Additionally, 2014A T651 offers good fatigue resistance, providing reliable performance under repeated loads and vibrational conditions.

Regarding machinability, 2014A T651 provides good surface quality and controlled chip breaking, consistent with other 2000 series aluminum alloys. It is suitable for CNC milling, drilling, turning, and other machining processes. The alloy has sufficient formability and can be subjected to operations such as bending, straightening, and pressing. However, its weldability is limited, and welding may negatively affect mechanical properties. Therefore, bolted connections or mechanical fastening methods are considered more reliable.

In terms of corrosion resistance, 2014A T651 is naturally limited due to its copper content. Surface protection is required in humid or aggressive environments. Therefore, protective treatments such as anodizing, coating, or painting are commonly applied. With appropriate surface protection, 2014A T651 provides long service life and reliable performance. This alloy is especially preferred in aerospace, defense, automotive, and heavy machinery industries where high strength and durability are required.

STANDARDS FOR MATERIAL COMPOSITION

2014A T651 can be supplied in accordance with the following standards:

• 2014A T651 Plate; ASTM B209, ISO AlCu4SiMg, UNS A9201, BS 2 L93, WNR 3.1255

• 2014A T651 Sheet; ASTM B209, ISO AlCu4SiMg, UNS A9201, BS 2 L93, WNR 3.1255

• 2014A T651 Cold Drawn Round Bar; ASTM B211, UNS A92014, ASTM B928

• 2014A T651 Cold Drawn Flat Bar; ASTM B211, UNS A92014, ASTM B928

• 2014A T651 Cold Drawn Wire; ASTM B211, UNS A92014, ASTM B928

• 2014A T651 Cold Drawn Tube; ASTM B211, UNS A92014, ASTM B928

Characteristic Properties of 2014A T651:

- Strength: Excellent

- Machinability: Very Good

- Weldability: Weak (Filler welding is the best option)

- Formability: Good

- Corrosion Resistance: Poor (Improves with coating)

- Heat Treatment: Yes

Some Well-Known Applications of 2014A T651:

Heat exchangers, cooling towers,

Military vehicle manufacturing and weapon production,

Generally used in aerospace and automotive industries.

STOCK

We supply 2014A T651 in plate/sheet, bar/flat bar, and tube/profile forms.

- Plate / Sheet

- Sheet

- Bar / Flat Bar

- Tube / Profile

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Up to & incl 2.5 | 370 MPa | 415 MPa | %6 |

| Over 2.5 up to and incl. 10 | 385 MPa | 435 MPa | %6 |

| Over 10 up to and incl. 25 | 415 MPa | 460 MPa | %7 |

| Over 75 up to and incl. 100 | 435 MPa | 480 MPa | %7 |

| Over 100 up to and incl. 150 | 420 MPa | 465 MPa | %7 |

| Over 150 up to and incl. 200 | 390 MPa | 435 MPa | %7 |

Weight Calculator

Weight Calculator