Cold Drawn Round Bar

Cold Drawn Tube

2017

Cold Drawn/Finished (CF) / AlCu4MgSi (Soğuk Çekim) / 2017 / T3

| Chemical Properties | % Value |

| Silicon (Si) | 0,20 - 0,80 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,40 - 1,0 |

| Magnesium (Mg) | 0,40 - 1,00 |

| Copper (Cu) | 3,50 - 4,50 |

| Titanium (Ti) | 0,00 - 0,25 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.79 g/cm³ |

| Melting Point | 513 °C |

| Thermal Expansion | 22.9 µm/m.°C |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 134 W/m-K |

| Electrical Resistivity | 38 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 240 MPa |

| Yield Strength | 430 MPa |

| Shear Strength | 260 MPa |

| Elongation A50 mm | 17% |

| Hardness | 105 HB |

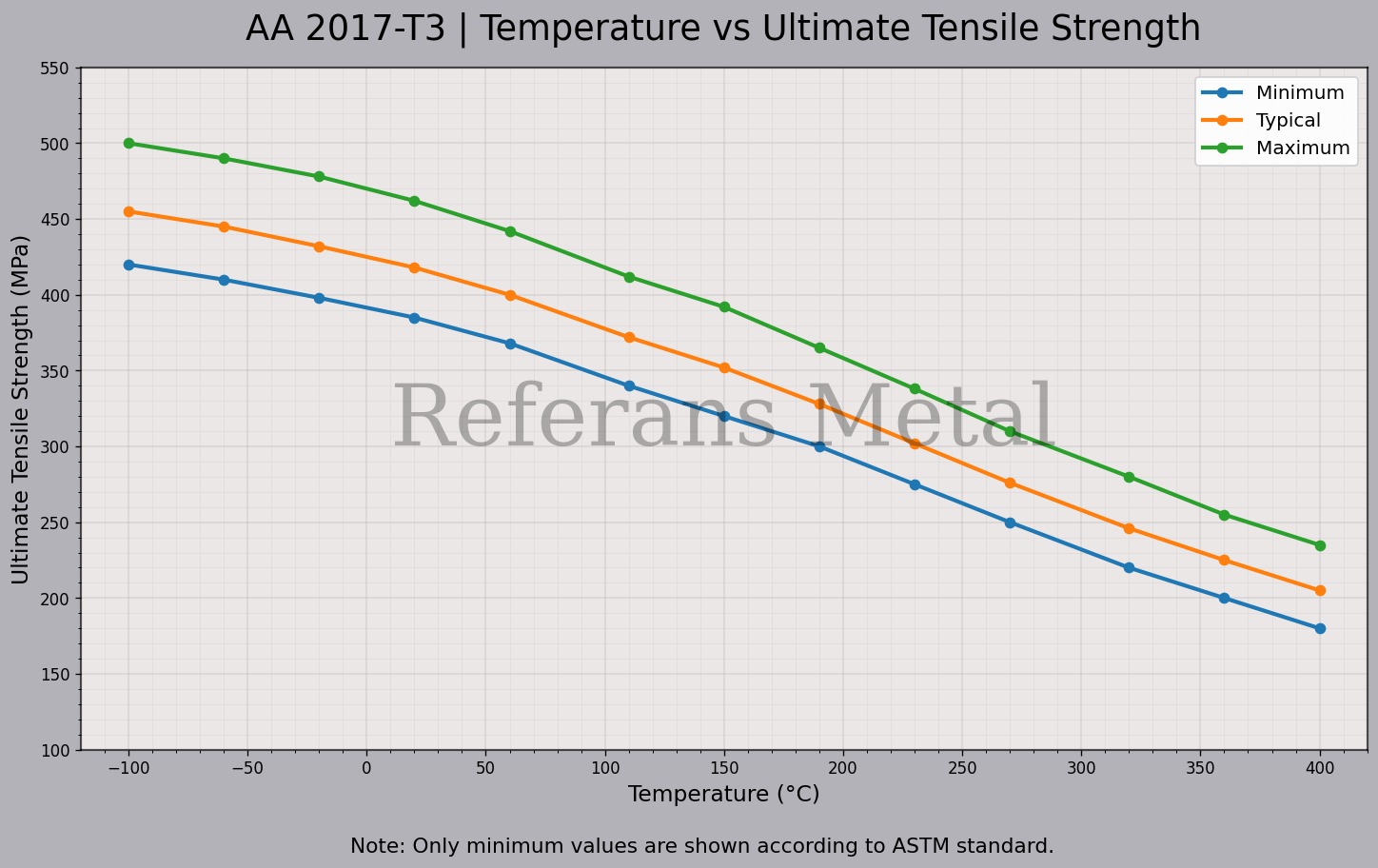

| 2017 T3 Temperature – Ultimate Tensile Strength Graph |

|

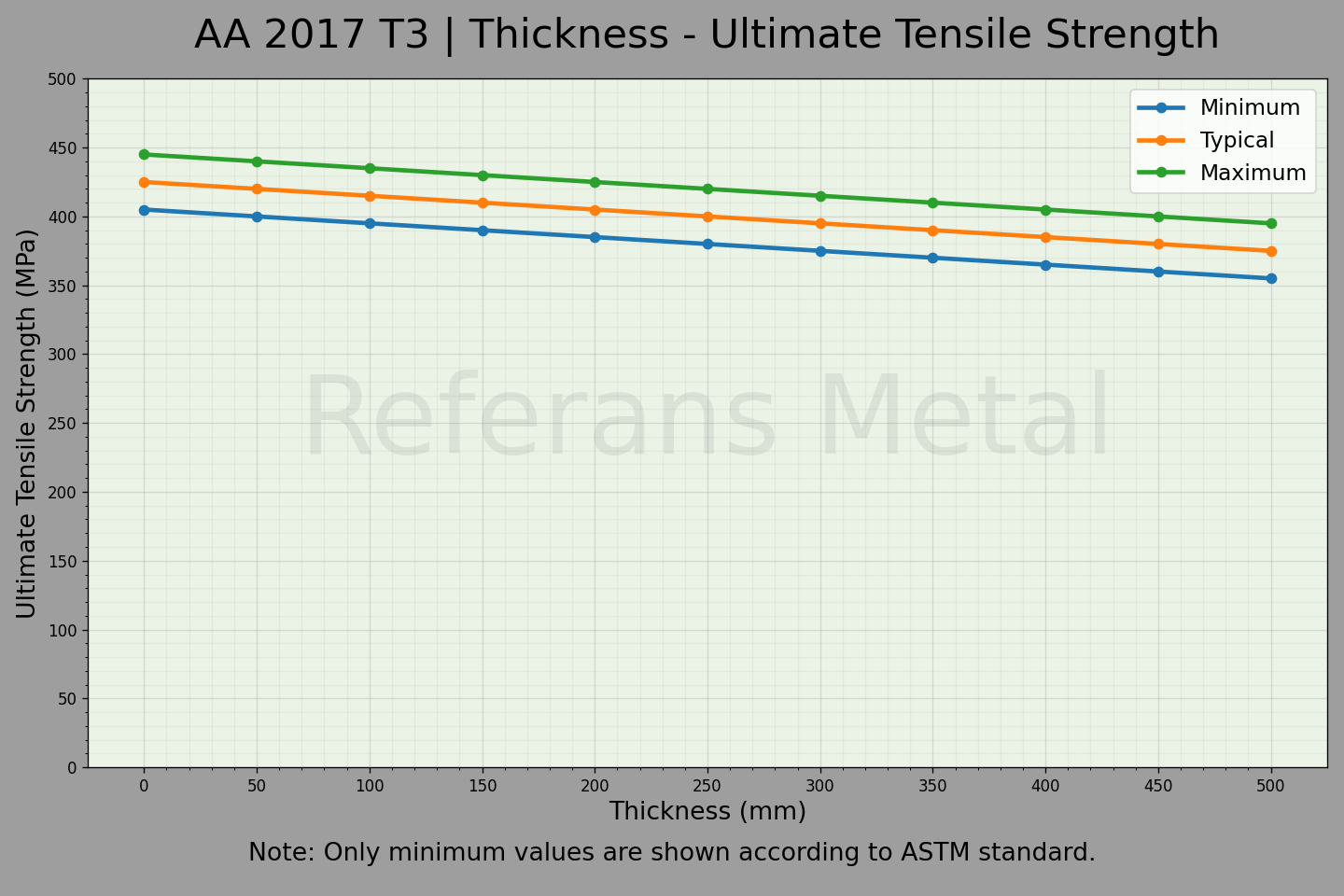

| 2017 T3 Thickness – Ultimate Tensile Strength Graph |

|

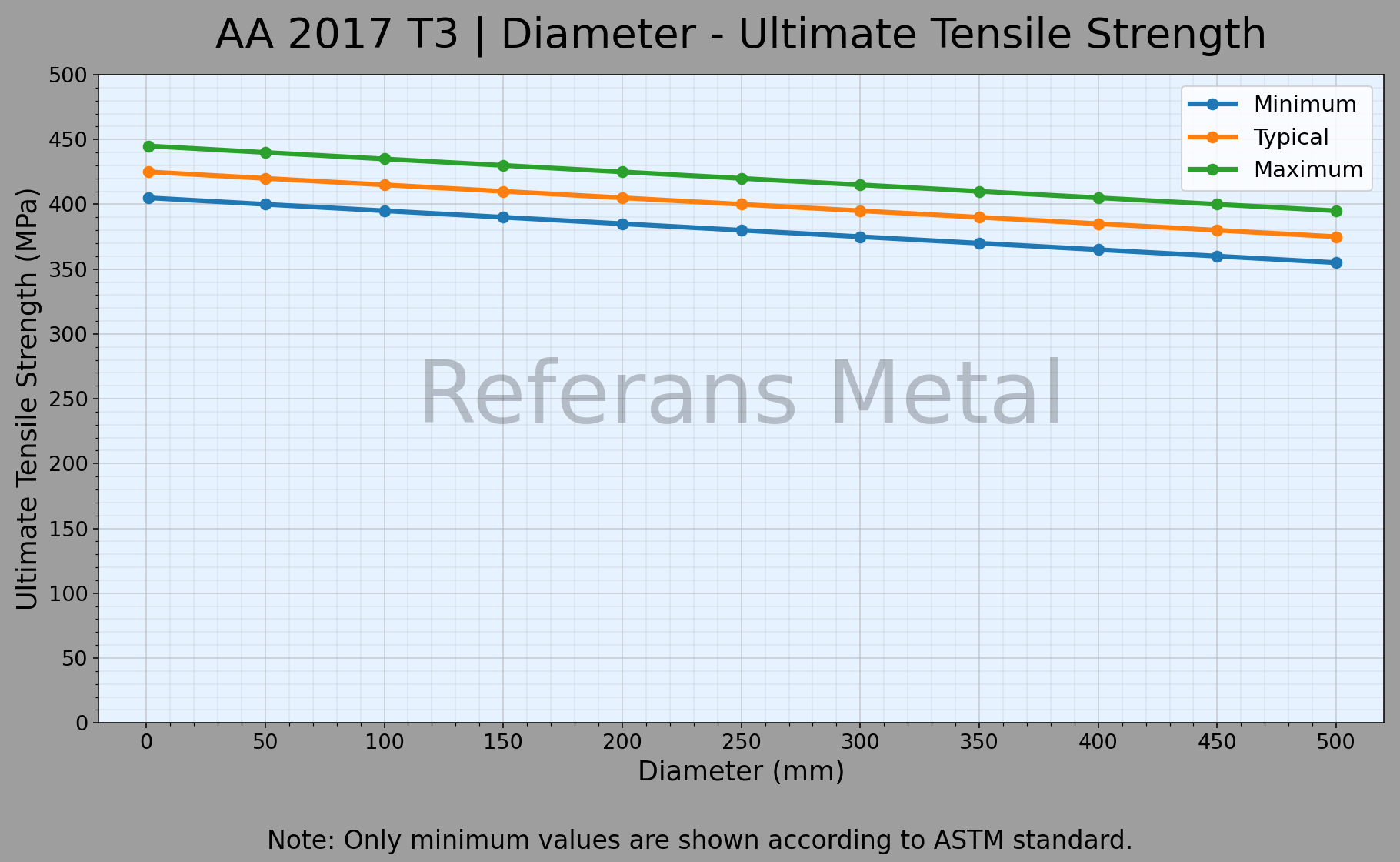

| 2017 T3 Diameter – Ultimate Tensile Strength Graph |

|

2017 T3 is a high-strength aluminum alloy of the 2000 series, reinforced with copper (Cu). The "T3" temper indicates that the alloy has been solution-treated, then cold-worked and naturally aged to achieve a stable condition. These thermal and mechanical processes reduce internal stresses while providing high strength, offering advantages for engineering applications requiring dimensional stability and precise tolerances. The alloy's chemical composition consists of an Al matrix with approximately 3.5–4.5% Cu, 0.4–1.0% Mn, 0.4–0.8% Mg, and 0.2–0.8% Si, which can be hardened through heat treatment to improve mechanical performance.

In terms of strength, 2017 T3 is very robust; its typical tensile strength is around 430 MPa, and its shear strength is approximately 260 MPa. The elongation is about 17%, making the alloy suitable for high-load structural components, aircraft parts, defense equipment, and heavy machinery structures. Additionally, 2017 T3 has good fatigue resistance, providing reliable performance under repeated loading and vibrational conditions. Therefore, it is widely used in industries with demanding operating conditions, such as aerospace and automotive.

Regarding machinability, 2017 T3 exhibits typical characteristics of the 2000 series, with controlled chip formation. This ensures good surface quality during machining processes like CNC milling, drilling, or turning and reduces tool wear. The alloy also has adequate formability, allowing bending, straightening, and stamping operations to be performed easily. However, its weldability is limited, and welding can negatively affect mechanical properties. Therefore, bolted or other mechanical fastening methods are usually preferred.

In terms of corrosion resistance, 2017 T3 provides limited natural protection; the presence of copper makes the alloy more sensitive to humid or aggressive environments. Therefore, surface protection methods such as anodizing, coating, or painting are commonly applied. Proper surface protection ensures long service life and reliable performance. 2017 T3 is widely used in applications requiring high strength and good machinability, particularly in aerospace, defense, automotive, and heavy machinery components.

MATERIAL COMPOSITION STANDARDS

2017 T3 can meet the following standards:

• 2017 T3 Cold-Drawn Round Bar; AMS QQ-A-225/5, ASTM B211, UNS A92017, WNR 3.1325, DIN AlCuMg1, ASTM B565, ASTM B316, ISO AlCu4MgSi

• 2017 T3 Cold-Drawn Tube; AMS QQ-A-225/5, ASTM B211, UNS A92017, WNR 3.1325, DIN AlCuMg1, ASTM B565, ASTM B316, ISO AlCu4MgSi

• 2017 T3 Cold-Drawn Flat Bar; AMS QQ-A-225/5, ASTM B211, UNS A92017, WNR 3.1325, DIN AlCuMg1, ASTM B565, ASTM B316, ISO AlCu4MgSi

• 2017 T3 Cold-Drawn Profile; AMS QQ-A-225/5, ASTM B211, UNS A92017, WNR 3.1325, DIN AlCuMg1, ASTM B565, ASTM B316, ISO AlCu4MgSi

Characteristics of 2017 T3:

- Strength: Excellent

- Machinability: Above Average

- Weldability: Moderate (Filling welding and brazing preferred)

- Formability: Good

- Corrosion Resistance: Moderate (Improved with coating)

- Heat Treatment: Yes

Common Applications of 2017 T3:

Used in rivets and fasteners, coat hangers,

as aerospace material,

and in the transportation sector, including military equipment and vehicles.

Stock

2017 T3 is available and supplied in sheet, bar/flat, and tube/profile forms.

- Bar / Flat

- Tube / Profile

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 25 up to & incl. 75 | 270 MPa | 400 MPa | %10 |

| Over 75 up to & incl. 150 | 260 MPa | 390 MPa | %9 |

| Over 150 up to & incl. 200 | 240 MPa | 370 MPa | %8 |

| Over 200 up to & incl. 250 | 220 MPa | 360 MPa | %7 |

Weight Calculator

Weight Calculator