Cold Drawn Round Bar

Cold Drawn Tube

6026

Cold Drawn/Finished (CF) / AlMg2.5SiMnCu (Soğ. Çekim) / 6026 / T9

| Chemical Properties | % Value |

| Silicon (Si) | 0,60 - 1,40 |

| Chromium (Cr) | 0,00 - 0,30 |

| Manganese (Mn) | 0,20 - 1,00 |

| Magnesium (Mg) | 0,60 - 1,20 |

| Copper (Cu) | 0,20 - 0,50 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,30 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.63 g/cm³ |

| Melting Point | 582 °C |

| Thermal Expansion | 23.4 µm/m.°C |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 170 W/m.K |

| Electrical Resistivity | 0,039 Ωmm² /m |

| Mechanical Properties | Value |

| Proof Strength | 330 MPa |

| Yield Strength | 360 MPa |

| Shear Strength | 250 MPa |

| Elongation A50 mm | 4% |

| Hardness | 95 HB |

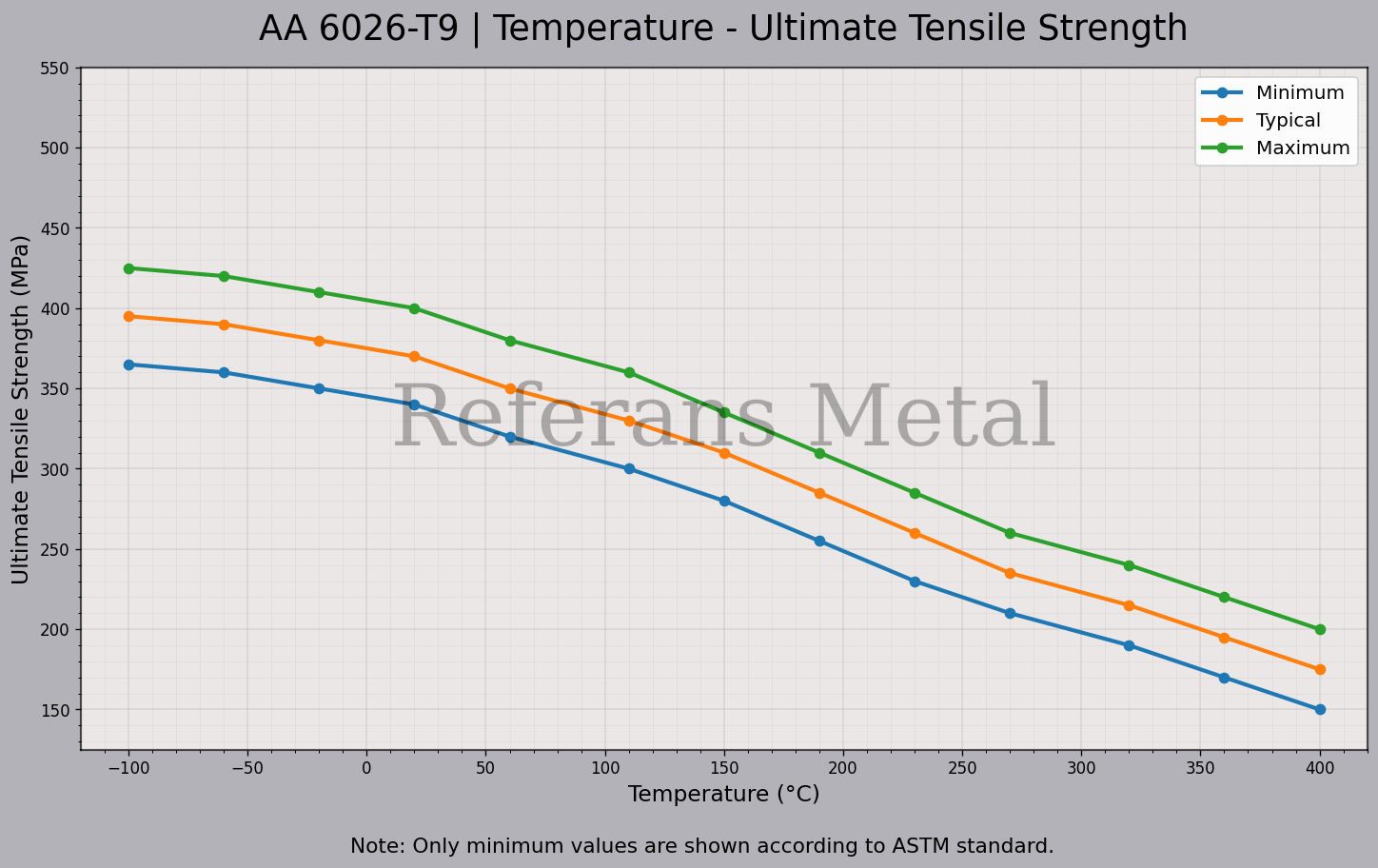

| 6026 T9 Temperature – Tensile Strength Graph |

|

The 6026 T9 aluminum alloy belongs to the 6000 series aluminum-magnesium-silicon (Al-Mg-Si) group and, in T9 temper (solution heat-treated, rapidly cooled, and then artificially aged to a higher degree), offers high strength and superior mechanical properties. The T9 temper allows the alloy to be processed to a higher aging level compared to T8 temper, making it harder and more durable. Chemically, 6026 T9 typically contains 0.8–1.3% silicon and 0.4–0.7% magnesium, along with small amounts of copper, chromium, and iron as trace elements. This composition combines high strength with low weight, making it an ideal material for engineering applications.

In terms of mechanical properties, 6026 T9 stands out with its high strength. Its tensile strength typically ranges from 360–400 MPa, while yield strength is approximately 320–360 MPa. These high strength values make the alloy suitable for load-bearing structural components, automotive and aerospace chassis parts, and engineering components that require durability. Additionally, the T9 temper increases hardness while maintaining a certain level of ductility, keeping the risk of fracture low.

In terms of machinability, 6026 T9 performs well despite its high hardness. It can be used for CNC milling, drilling, and cutting operations; using the correct cutting tools and processing parameters ensures quality surface finishes. Due to the alloy's high hardness, careful attention is required during machining in T9 temper, including appropriate cooling and tool selection. Furthermore, 6026 T9 alloy can be welded with high quality and durability using methods such as MIG and TIG. However, the localized heat generated during welding may partially affect mechanical properties, so precautions are recommended for critical applications.

Regarding corrosion resistance, 6026 T9 is highly resistant to atmospheric conditions and mild seawater environments. The naturally formed thin and dense oxide layer on the material surface acts as a barrier against rust and general corrosion. In more aggressive or chloride-containing environments (such as open seawater), additional protection through anodizing or suitable coating methods can extend the alloy's lifespan. These characteristics make 6026 T9 a suitable choice for automotive, aerospace, defense, and high-performance engineering applications.

STANDARDS OF MATERIAL COMPOSITION

6026 T9 can be produced according to the following standards:

• 6026 T9 Cold Drawn Round Bar; 2000/53/CE-ELV (for automotive), 2002/95/CE-RoHS, ASTM B211, UNS A96026

• 6026 T9 Cold Drawn Sheet; 2000/53/CE-ELV (for automotive), 2002/95/CE-RoHS, ASTM B211, UNS A96026

Characteristic Properties of 6026 T9:

- Strength: Average

- Machinability: Above Average

- Weldability: Moderate

- Formability: Moderate

- Corrosion Resistance: Good

- Heat Treatable: Yes

Some Well-Known Applications of 6026 T9:

Parts with hard anodized coatings,

Brake systems,

Also used in pneumatic applications.

STOCK

We produce and supply 6026 T9 in rod/sheet and tube/profile forms.

- Rod / Sheet

- Tube / Profile

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 0.2 up to & incl. 0.5 | 241 | 290 | %8 |

| Over 0.5 up to & incl. 6.5 | 241 | 290 | %10 |

Weight Calculator

Weight Calculator