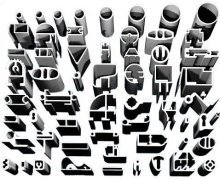

لوحات/ طباقات

صاج

قضيب

أنابيب

2024

ASME SB221 / AlCu4Mg1 / 2024 / T651

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,50 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,30 - 0,90 |

| Magnesium (Mg) | 1,20 - 1,80 |

| Copper (Cu) | 3,80 - 4,90 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.78 g/cm³ |

| Melting Point | 502 °C |

| Thermal Expansion | 22.9 µm/m.°C |

| Modulus of Elasticity | 73.1 GPa |

| Thermal Conductivity | 151 W/m.K |

| Electrical Resistivity | 30% IACS |

| Mechanical Properties | Value |

| Proof Strength | 427 MPa |

| Yield Strength | 455 MPa |

| Shear Strength | 296 MPa |

| Elongation A50 mm | 7% |

| Hardness | 128 HB |

ALLOY DESIGNATIONS

Aluminium alloy 2024 T651 has similarities to the following standard designations and specifications:

Extruded round, flat bars per: 2024 T651, AMS QQ-A-200/3, ASTM B221

Choosing Factors for 2024 T651

- Strength: Good

- Machining: Above average

- Weldability: Medium (Spot welding is the best choice)

- Formability: Weak

- Corrosion Resistance: Low

- Heat Treating: Yes

Some Well-Known Applications for 2024 T651

It is used in the automotive industry,

As well as in airframe structures.

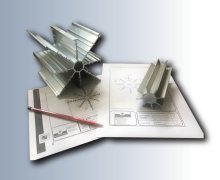

SUPPLIED FORMS

2024 T651 is supplied in round/flat bar and tube/ profile forms.

- Flat/round bar

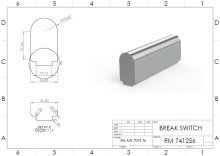

DELIVERY:

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| over 6,35 up to & incl. 12,7 mm | 400 MPa | 460 MPa | ≥%5 |

| over 12,7 up to & incl. 25,4 mm | 400 MPa | 455 MPa | ≥%5 |

| over 25,43 up to & incl. 38,07 mm | 395 MPa | 455 MPa | ≥%5 |

حساب الوزن

حساب الوزن