Листы/Плиты

Лист

Бар/Листовая Сталь

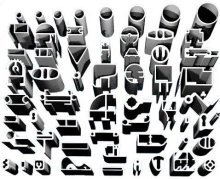

Трубы/Профили

5083

AMS QQ-A-250/6 / AlMg4.5Mn0.7 / 5083 / H14

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,70 |

| Tin (Sn) | 0,50 - 0,90 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,40 - 1,00 |

| Magnesium (Mg) | 4,00 - 4,90 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,40 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.66 g/cm³ |

| Melting Point | 570 °C |

| Thermal Expansion | 24.2 µm/m.°C |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 117 W/m-K |

| Electrical Resistivity | 29 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 290 MPa |

| Yield Strength | 360 MPa |

| Shear Strength | 210 MPa |

| Elongation A50 mm | 3.4 % |

| Hardness | 100 HB |

5083 H14 aluminum alloy is known for its excellent corrosion resistance, high strength, and good formability. Alloyed with magnesium and manganese, 5083 is widely used in the marine, defense, and transportation industries. The H14 temper indicates that the material has been partially strain-hardened without undergoing solution heat treatment, offering a balance of moderate strength, workability, and durability.

5083 H14 is commonly used in marine applications (shipbuilding, watercraft), storage tanks, automotive components, and industrial equipment. It is highly suitable for anodizing, forming a uniform oxide layer that enhances corrosion resistance and provides an aesthetically pleasing finish. In terms of weldability, it performs exceptionally well and can be easily joined using standard MIG and TIG welding methods. After welding, it retains much of its structural strength, making it a reliable material for structural applications.

When it comes to bending and forming, 5083 H14 aluminum alloy offers good flexibility, allowing for the creation of complex shapes. This characteristic makes it ideal for projects requiring precise shaping. It also performs well in high-vibration environments, maintaining durability and fatigue resistance under dynamic loads. This makes it a dependable choice for applications subjected to significant vibrations and stresses.

The corrosion resistance of 5083 H14 is one of its strongest features. It demonstrates exceptional durability in harsh conditions such as saltwater, chemicals, and humid environments. However, it is not as hard as higher-strength alloys, which can limit its use in applications requiring very high load-bearing capacity. Its advantages include excellent corrosion resistance, good weldability, and formability, while its disadvantages include limited hardness and restricted use in high-strength applications. These properties make 5083 H14 an ideal choice for projects requiring lightweight materials with durability and versatility.

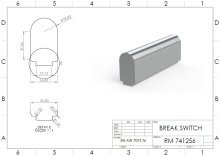

Sheets per; 5083 H14, ASTM B209, AMS QQ-A-250/6, DIN AlMg4.5Mn, ISO AlMg4.5Mn0.7, WNR 3.3547

Seamless Extruded Tubes per; 5083 H14, ASTM B241, AMS QQ-A-200/4, DIN AlMg4.5Mn, ISO AlMg4.5Mn0.7, WNR 3.3547

Choosing Factors for 5083 H14

- Strength: Very good

- Machining: Poor

- Weldability: Okay

- Formability: Average

- Corrosion Resistance: Excellent

- Heat Treating: None

Some Well-Known Applications for 5083 H14

In shipbuilding industry,

In storage tanks in the marine industry,

Also it is used in pressure vessels and vehicle chassis.

- Tube/Profile

- Round/Flat Bar

- Sheets

Калькулятор Веса

Калькулятор Веса