Platos

Hojas

Barras Circulares

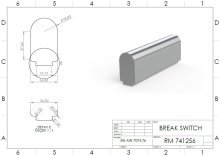

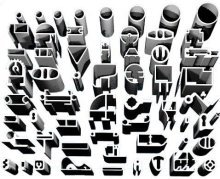

Tubos / Extrusion / Perfil

7178

ASTM B221 / AlZn7MgCu / 7178 / T6511

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,40 - 3,10 |

| Copper (Cu) | 1,60 - 2,40 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 6,30 - 7,30 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,83 g/cm³ |

| Melting Point | 479 °C |

| Thermal Expansion | 23.5 x 10^-6 /K |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | 31% IACS |

| Mechanical Properties | Value |

| Proof Strength | 560 MPa |

| Yield Strength | 630 MPa |

| Shear Strength | 370 MPa |

| Elongation A50 mm | 5% |

| Hardness | 160 HB |

7178 T6511 is a high strength aerospace aluminium alloy with good resistance to stress-corrosion cracking.

ALLOY DESIGNATIONS

7178 T6511 has the following standard designations and specifications.

As Cold Drawn Round/Flat Bar and Tube; 7178 T6511, UNS A97178, ASTM B211, ISO AlZn7MgCu, QQ-A-430

As Extruded Profile; 7178 T6511, AMS QQ-A-200/13, ASTM B221, SAE J454, UNS A97178, ISO AlZn7MgCu

Choosing Factors for 7178 T6511

- Strength: Excellent

- Machining: Poor

- Weldability: Average

- Formability: Okay

- Corrosion Resistance: Okay

- Heat Treating: Yes

Some Well-Known Applications for 7178 T6511

It is used in brake pads in the automotive industry,

In addition to the aerospace industry,

It is also used in the construction industry.

SUPPLIED FORMS

7178 T6511 is produced/supplied in round/flat bar and tube/profile forms.

- Tube/Profile

- Round/Flat Bar

DELIVERY:

Calculador de Peso

Calculador de Peso