Barres Étirées à Froid

Tubes Étirés à Froid

2007

Cold Drawn/Finished (CF) / AlCu4PbMgMn (Soğuk Çekim) / 2007 / T351

| Chemical Properties | % Value |

| Silicon (Si) | 0,80 Max |

| Copper (Cu) | 3,30 - 4,60 |

| Lead (Pb) | 0,80 - 1,50 |

| Iron (Fe) | 0,80 Max |

| Zinc (Zn) | 0,00 - 0,80 |

| Nickel (Ni) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| Magnesium (Mg) | 0,40 - 1,80 |

| Manganese (Mn) | 0,50 - 1,00 |

| Physical Properties | Value |

| Density | 2.82 g/cm³ |

| Melting Point | 510 °C |

| Thermal Expansion | 23.0 µm/m.°C |

| Modulus of Elasticity | 73 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | %47 IACS |

| Mechanical Properties | Value |

| Proof Strength | 270 MPa |

| Yield Strength | 410 MPa |

| Shear Strength | 240 MPa |

| Elongation A50 mm | 6% |

| Hardness | 105 HB |

An aluminum-copper alloy that typically contains between 4.0 and 5.0 % of copper, it is suitable for producing machine parts, bolts and rivets. It resembles very much to 2011 alloy, while being a bit more harder.

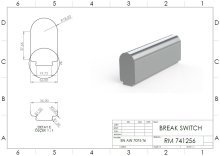

Cold Drawn Round/Flat Bars per; 2007 T351, WNR 3.1645, DIN AlCuMgPb, AFNOR A-U4Pb, UNI 9002/8, UNE L-3121, UNS A92007, ISO AlCu4PbMgMn

Cold Drawn Tubes per; 2007 T351, WNR 3.1645, DIN AlCuMgPb, AFNOR A-U4Pb, UNI 9002/8, UNE L-3121, UNS A92007, ISO AlCu4PbMgMn

Choosing Factors for 2007 T351

- Strength: High

- Machining: Good

- Weldability: Weak

- Formability: Poor

- Corrosion Resistance: Poor

- Heat Treating: Yes

Some Well-Known Applications for 2007 T351

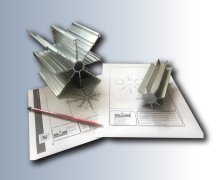

Milled and turned parts,

As components of fans,

It is also used in threaded rods.

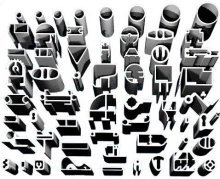

- Rod / Round Bar / Flat Bar

- Tube/Profile

Calculateur de Poids

Calculateur de Poids